ELASTIC MONOLITHIC CONVEYOR BELTS

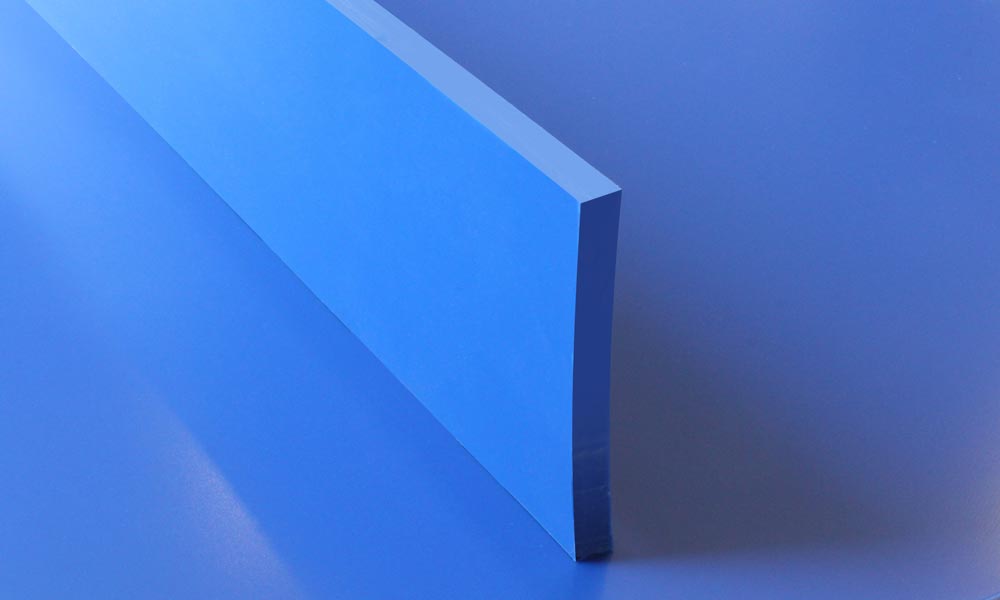

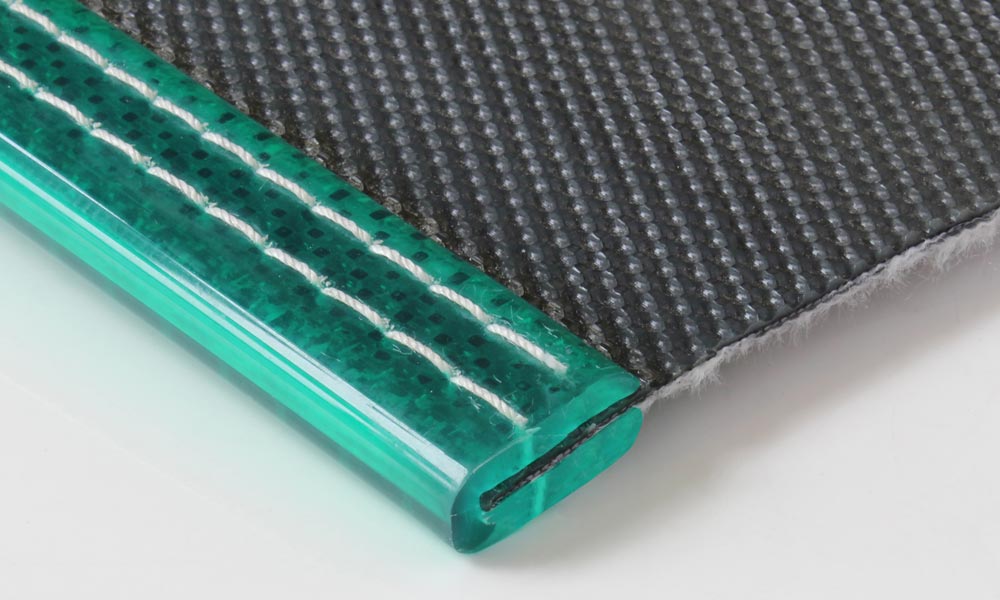

BEHAbelt offers a comprehensive portfolio of monolithic elastic conveyor belts and also slip-free AT5 conveyor belts for various industrial applications. Due to the steadily growing automation of industrial production processes and processing machines, new challenges are constantly arising. Only when all machine components keep pace with your product characteristics will real progress be made in terms of efficiency, capacity and safety. BEHAbelt’s conveyor belts and belting are purely monolithic; i.e. they are made entirely of polyurethane and do not require a fabric insert.

Thus, these belts allow for service life improvements and significantly minimize the risks in terms of food contamination that can occur due to stock separation or fraying.

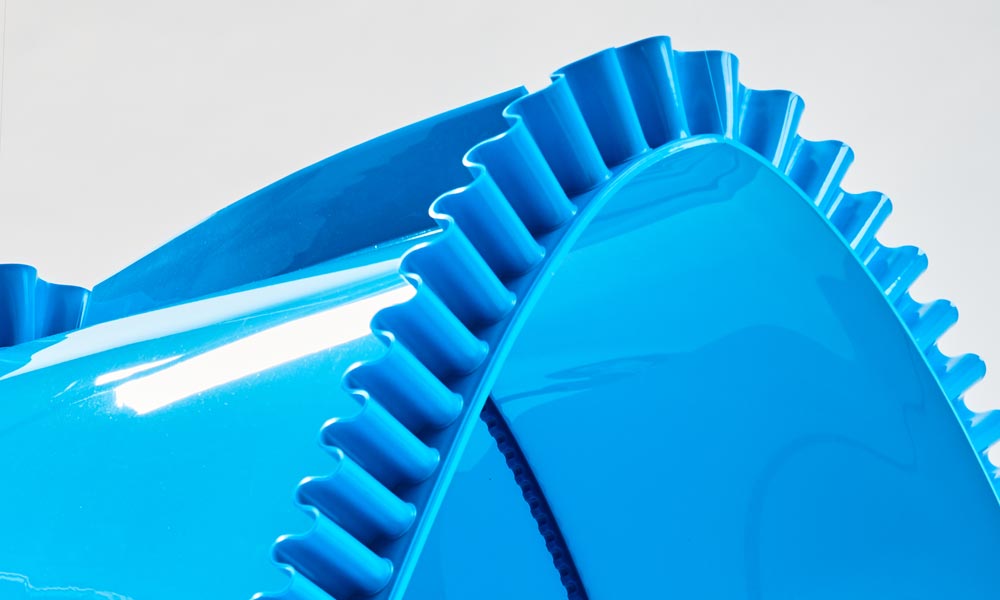

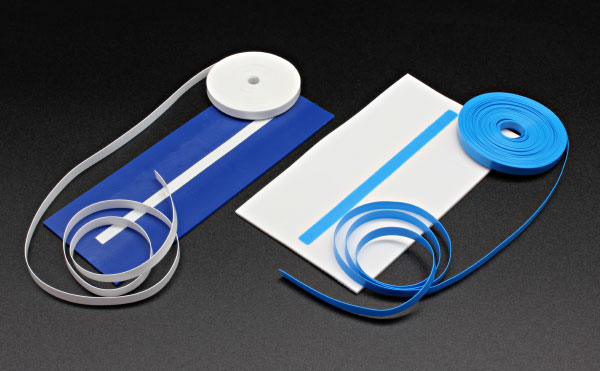

STRUCTURES OF THE CONVEYOR BELTS (750mm width)

Currently we offer 12 different structures, almost all of which can be combined with each other.

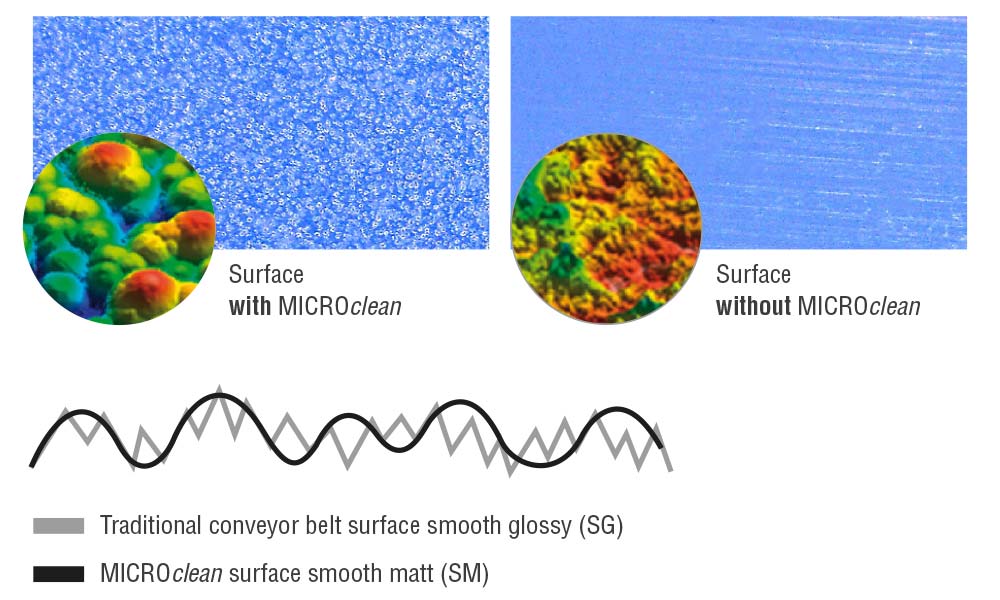

Five of them additionally have the unique surface finish “MICROclean”.

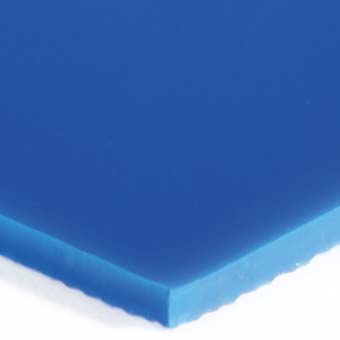

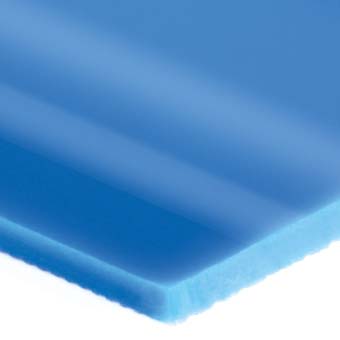

smooth Matt (SM)

microclean

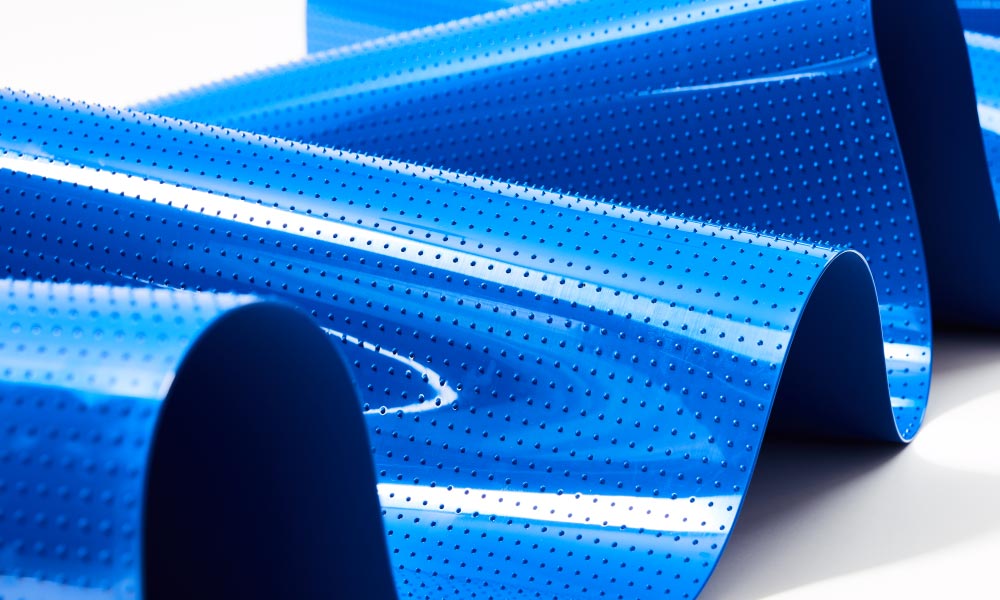

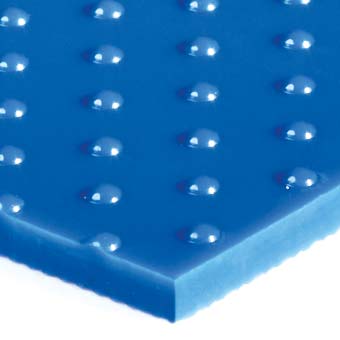

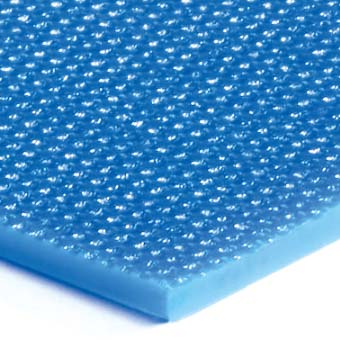

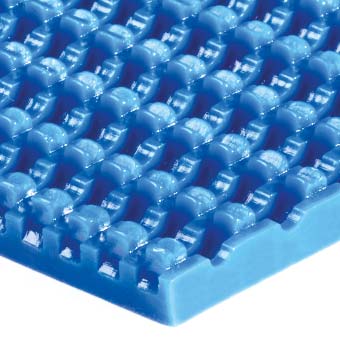

Nub top (NP)

microclean, from 1.6mm

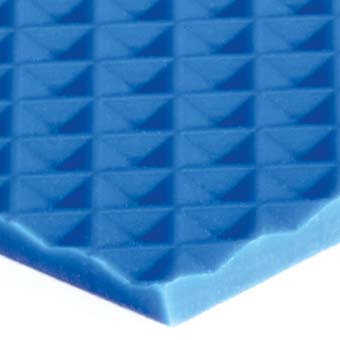

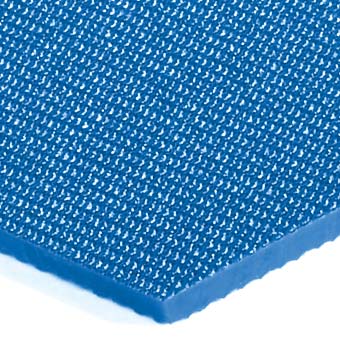

inverted diamond (ID)

microclean, from 1.6mm

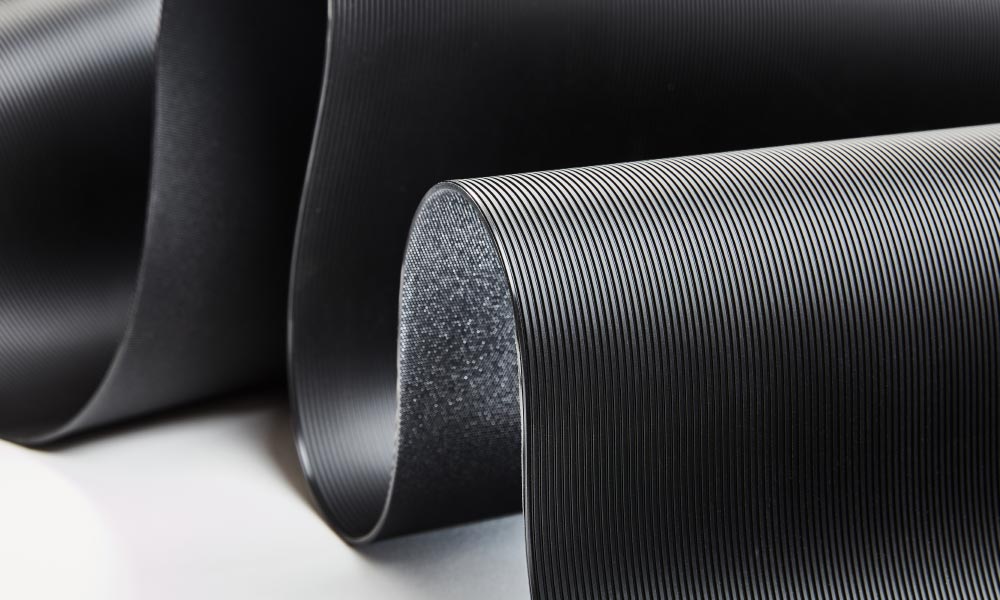

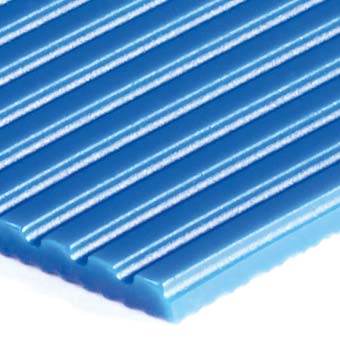

longitudinal grooves (LGB)

microclean, from 1.6mm

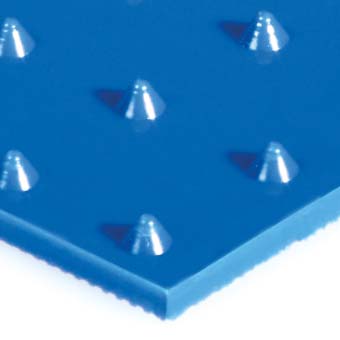

SPIKES (SP)

from 1.6mm

Slightly rough (SR)

transversal grooves (TGA)

microclean, from 2mm

smooth gloss (SG)

fabric impression (FI)

Supergrip (ESG)

width up to 360mm