The processing of sausage, cheese and meat requires a very high degree of precision and above all hygiene. The elastic conveyor belts and belt profiles from BEHAbelt provide significant support for your processes:

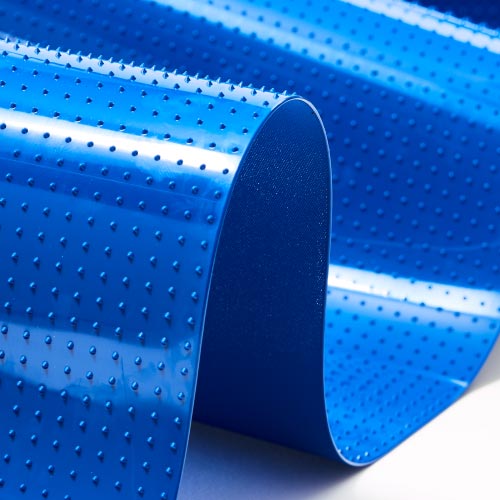

The products are made of 100% PU and therefore do not require any fabric at all. This means they remain elastic and can be easily installed. No use of fabric minimises the risk of microbes forming on edges or damaged areas on the conveyor belt.

Slicer

Check weighers

Detection systems

Spreading applications

Compensators

Picker systems

Labelling systems

Packaging machines

Positioning in and out

Buffer sections

Product In-Feed

Process description / Requirement

In addition to optical systems, such as X-ray scanners or LED camera systems, the loading or feeding process in product preparation also includes belt markings for the correct pre-positioning of the raw material.

If the preparation process functions are optimal, a repeat accuracy by the subsequent work steps can be carried out efficiently.

Suitable products

The raw product (sausage, ham and cheese) is usually still comparatively heavy.

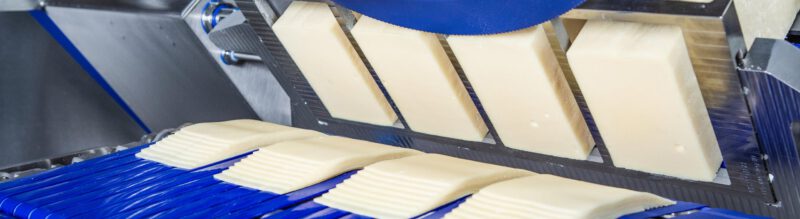

Slicer

Process description / Requirement

Whether soft cheese or hard raw ham: slicing systems are designed to deliver excellent performance through simple operation.

In addition to the precise slicing processes, hygiene and maintenance are very important factors. The open frame design makes cleaning and maintenance easy.

- Sausage, ham, meat, bacon, cheese, products made from vegetable proteins

- Highest precision

- Easy maintenance and cleaning

Suitable products

Elastic monolithic belts do not have any fabric, thus providing no opportunity for microbial growth and are resistant to water and moisture due to hydrolysis resistance. The AT5 variants also offer slip-free transport, which is perfect for slicers.

Both the friction and slip-free belts can be produced with different surfaces (spike, nub top, diamond)

Buffer area

Process description / Requirement

This area between slicer and packaging can contain a wide variety of operations:

Cassette systems, lateral overlapping, buffer operation, compensator, positioning in and out, spreading, grouping or separating. Depending on the material being conveyed, the release properties are a big factor in the right choice of conveyor belt.

BEHAbelt conveyor belts allow to minimize the radii of the transfer points.

Suitable products

- The unique surface finish “MICROclean” not only ensures the best cleanability, but also provides optimum release properties.

- The slip-free AT5 conveyor belts are ideal for the precise and continuous feeding of indexing packaging machines. They offer the highest precision and the best hygiene.

- For spreading applications, smaller belts are used and for wider angles, belt profiles (round, V-belt and T-profiles) are preferred.

Packaging

Process description / Requirement

Efficiency and the highest hygiene requirements ensure optimum production life and thus cost-effectiveness in packaging.

After the upstream processes of feeding, cutting and transporting, seamless connection integration is essential here.

The processing requirements are very different:

- Various pack sizes (single or multiple varieties)

- Labelling and quality inspection

- Classic thermoformed, tray and pouch packaging

- Skin / shrink packaging

- Picker systems

Suitable products

UIn order to meet the high level of automation and precision, it is essential to coordinate the products to be processed with the conveyor belt. This is the only way to ensure that positioning accuracy, release properties and thus slippage are prevented.

Check Weighers

Process description / Requirement

Weight detection ensures compliance with legal requirements and industry regulations. The mostly automated weight inspection with maximum performance and repeatability contributes significantly to high economic efficiency and process reliablilty.

Depending on the nature of the objects to be weighed, very good releae properties and good cleanability are required. For this purpose, BEHAbelt offers an optimal surface refinement with the unique MICROclean surface.

Suitable products

For exact weight determination, the thinnest possible belts should be used, which also allow very small transfer points.

- Thin elastic monolithic conveyor belts (from 0,9 mm, PU80A)

- Bias splice

- Antistatic belt version

Detectors (Metal and X-ray)

Process description / Requirement

Product inspection systems for foreign object detection and quality control make a very important contribution to protecting the health of your customers.

With these detectors (metal or X-ray technology), contamination of food by foreign bodies can be reliably detected.

The detection sensitivities can be individually adjusted as required and are not normally affected by packaging.

- Packed and unpacked food

- Bulk goods (powder or grains)

- Pasty masses

Suitable products

Both the elastic monolithic belts and the non-reinforced belt profiles are suitable for trouble-free transport through the inspection area of metal and X-ray detectors. Thanks to the homogeneous design, the measurement results of the detectors are neither distorted nor influenced.

For upstream process sections, the PU80Asafe product series offers the possibility to detect and remove inadvertently inserted strip pieces downstream with a detector. This product series thus makes a preventive contribution to product safety.

- Round and V-belts, Conveyor belts

- Coatings and weld-on accessories for conveyor belts

- PU80safe series for upstream processes

Our motto is “smart conveying”. BEHAbelt is a specialist and provides detailed advice.

It is important to us to support you with our experience in selecting the most suitable belt or conveyor for your application. The resulting know-how from many applications shows us that there is potential for optimisation in most processes.

Request sample advice download brochureOverview of conveyor belts and belt profiles for processing sausage, cheese and meat

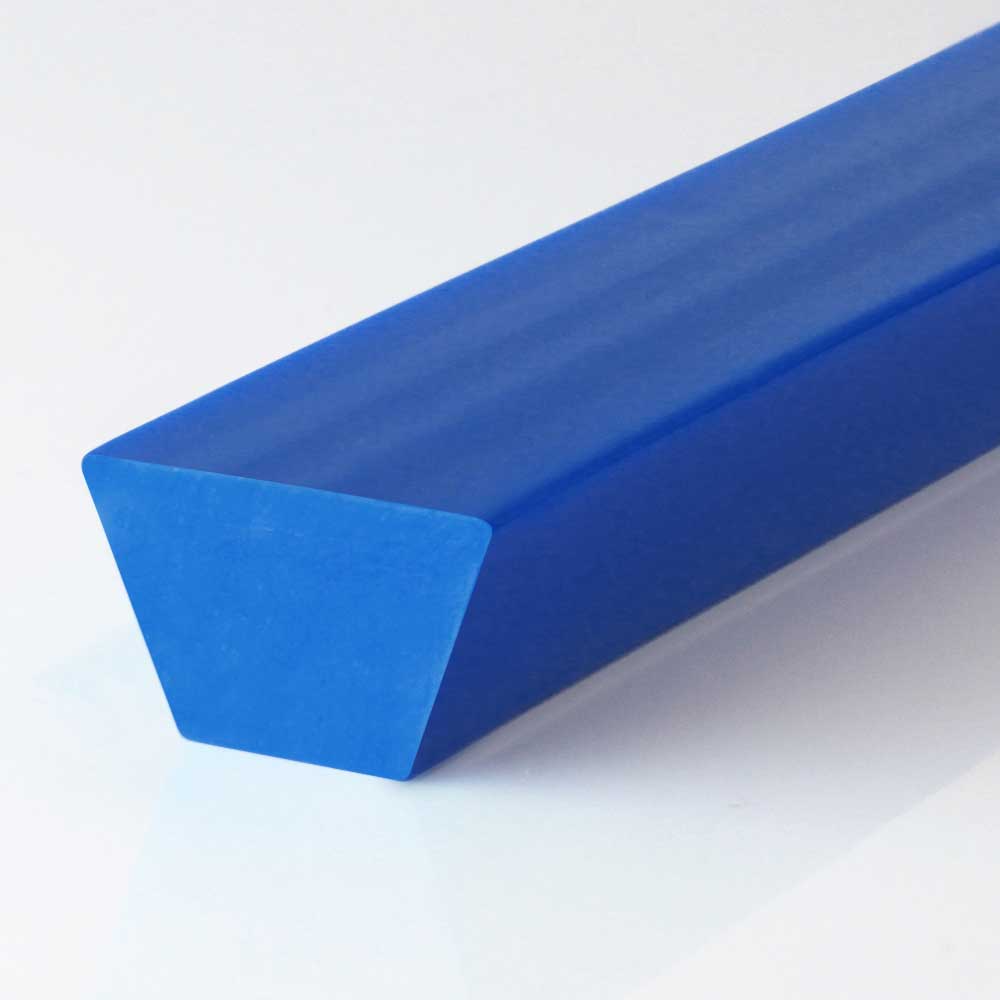

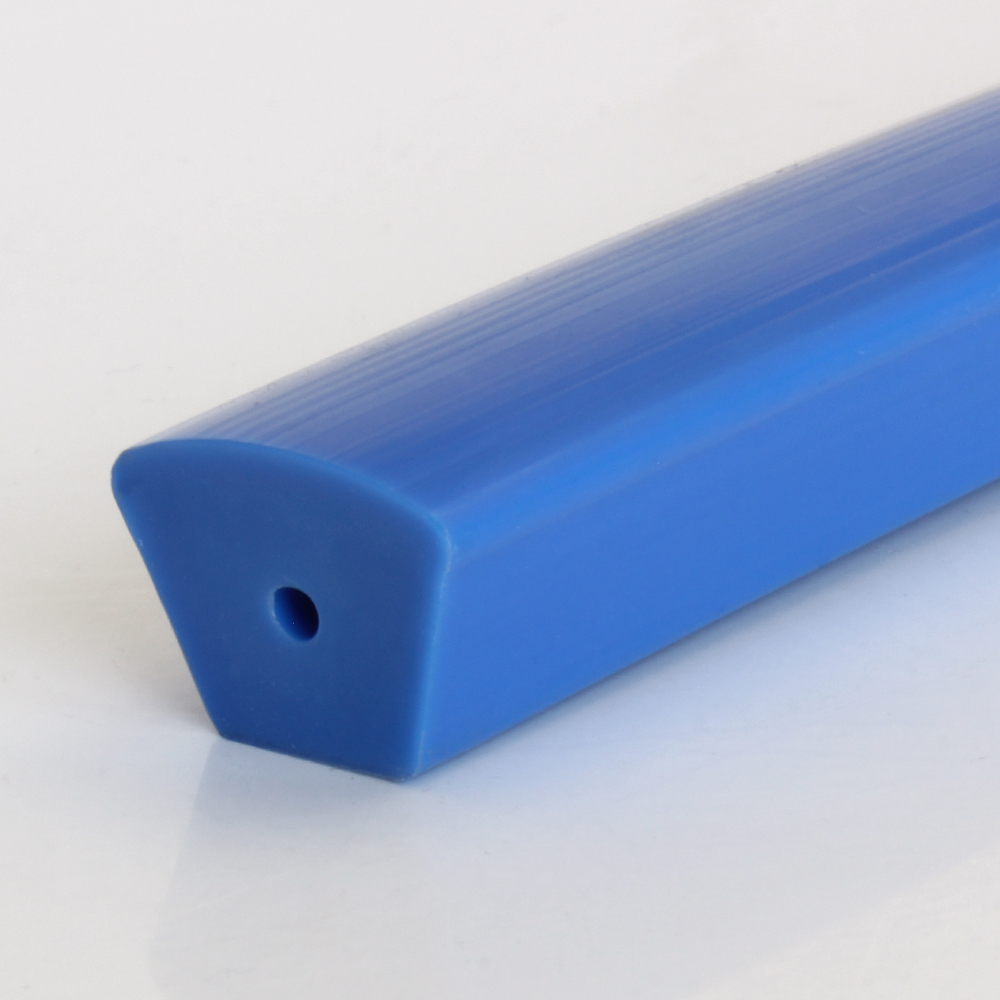

BEHAbelt processes high-quality PU and TPE materials for the production of belt profiles, which guarantee optimum performance and a long service life in conveyor technology and transmission applications. The belt profiles are approved for direct contact with food (FDA/USDA) and are resistant to hydrolysis and microbes.

The extruded belts are available in various Shore hardnesses and diameters. Depending on the requirements, they are reinforced, thus increasing the tensile load and tensile strength.

Both PU and TPE belt profiles are easy to weld. BEHAbelt supplies the belts either endlessly welded to your desired length or the belts can be welded independently on site.

Friction driven elastic conveyor belts

These conveyor belts are installed in the system with a pretension of 0.5…5%. The precise pretension ensures optimum power transmission and thus optimises the bearing load and ultimately your energy costs. The belts are guided e.g. via crowned pulleys or welded-on V-guides.

Weldable accessories for conveyor belts

Notched V-Guides are often used as guide profiles on the running side in order to support the straight running of e.g. short or under-square conveyor belts or to absorb cross forces in case of sidewise product feeding.

Cleats are for carrying single or bulk goods on inclined conveyors.

Sidewalls – ususally in combination with cleats on inclined or declined conveyor belts to prevent products from dropping sideways.

Welding tools for belt profiles and conveyor belts

For belt profiles:

Friction welding machine RS02

Butt welds in seconds with the unique RS02 friction welding machine for PU profiles.

For belt profiles and belt strips:

Hot paddle welder EErgo 60/90

The BEHAbelt EErgo 60 and 90 paddle welderss have been specially developed for joining PU and TPE profiles or belt strips.

For conveyor belts:

Welding Unit HS400 & HS800

With this welding unit, conveyor belts can be joined on site with process reliability by means of butt welding. Up to 800mm width.