Process reliable CRIMP splice for round belts with steel reinforcement

as an alternative to PU-coated steel cables

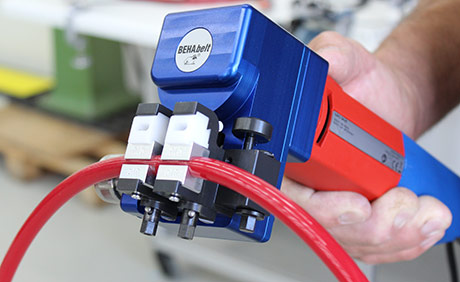

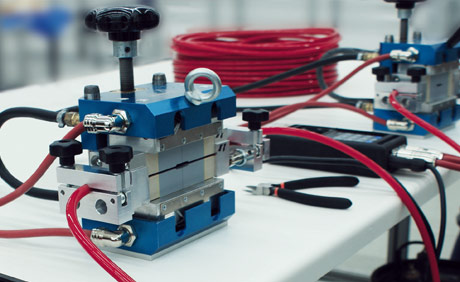

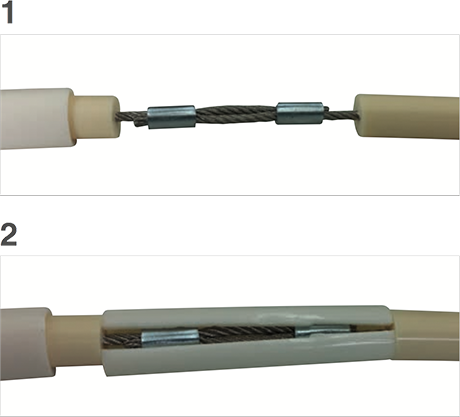

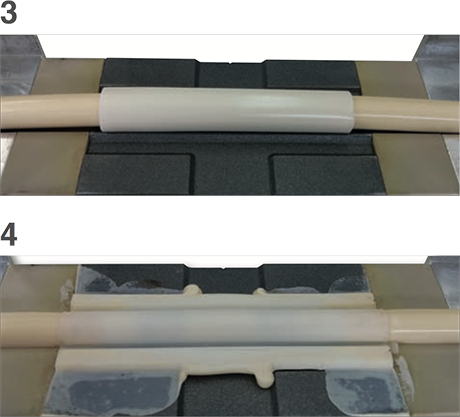

A special design form is the connection of round belts with steel reinforcements. In this case, the exposed reinforcement is connected with CU press sleeves and the resulting gap in the connection point is then filled again with material inserts. With the BEHAbelt hot press HP01 this part is pressed and connected with the remaining material. For the preparation of the connection point to be pressed BEHAbelt offers the connection set RH-2, which contains all necessary components.

This variant of the CRIMP connection is an ideal alternative to PU coated steel cables. These are usually connected with the very complex splicing technique.

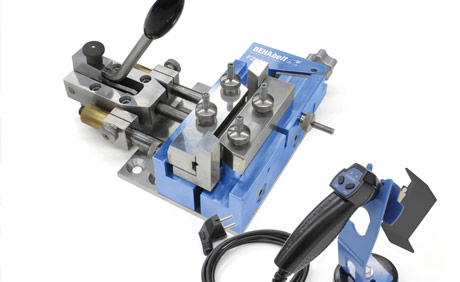

BEHAbelt CRIMP-Set RH-2

For connecting round belts with steel reinforcement.

Contains 1 pc. Nylon bag, 1 pc. RH-2 crimping tool, 3m polyester jacket inserts (outside/inside) and 100 CU clamps.

For round belt diameters 9.5 mm, 10 mm, 12 mm and 12.5 mm.

BEHAbelt Hot press HP01

Round and V-belts can be joined to the HP01 hot press by means of butt or overlap welding. The control PPuls Element ensures the optimum temperature and cooling time. The hot press reliably welds the prepared CRIMP joints.more

information about hot press