Keilleisten und Führungsprofile

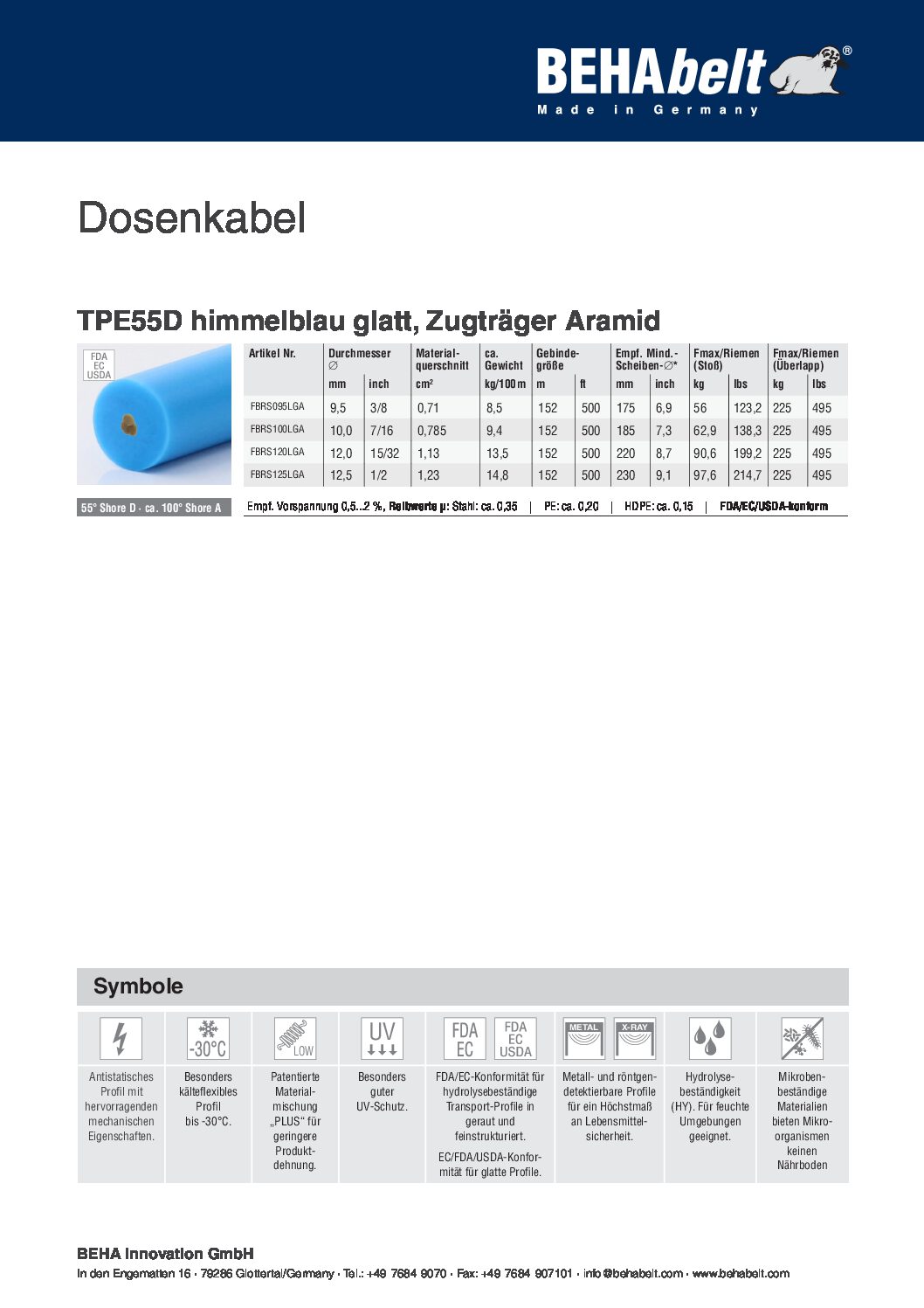

verschweißbare PU-Keilleisten für Transportbänder

Technische Beratung Muster anfordern

verschweißbare PU-Keilleisten für Transportbänder

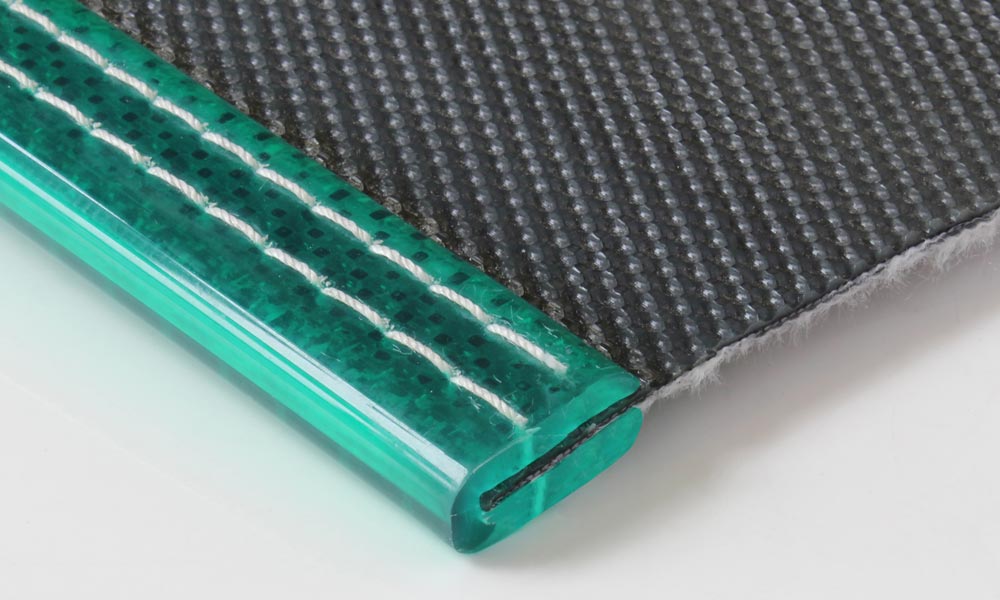

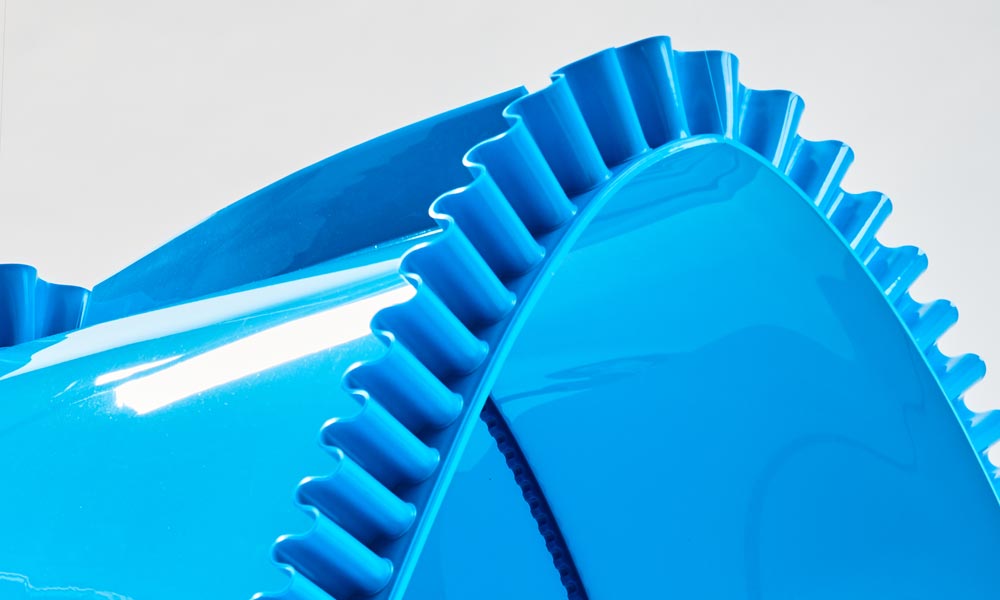

Technische Beratung Muster anfordernV-.guides are mainly used as guide profiles on the running side of conveyor belts. They are used to support the straight running of long and/or narrow conveyor belts or to absorb lateral forces when products are fed in from the side. On Z conveyors, the v-guide is guided in the groove of the pressure rollers. In other applications, v-guides are also used as a lateral limit to keep the conveyed product on the belt.

BEHAbelt offers a wide variety of extruded PU v-guides. This is reflected in the number of dimensions and geometries, but also in the type of properties, such as metal detectable.

The variety of applications on the market requires a wide product range. In addition to the short-term availability of standard products, we are happy to offer you the development and production of a customised profile.

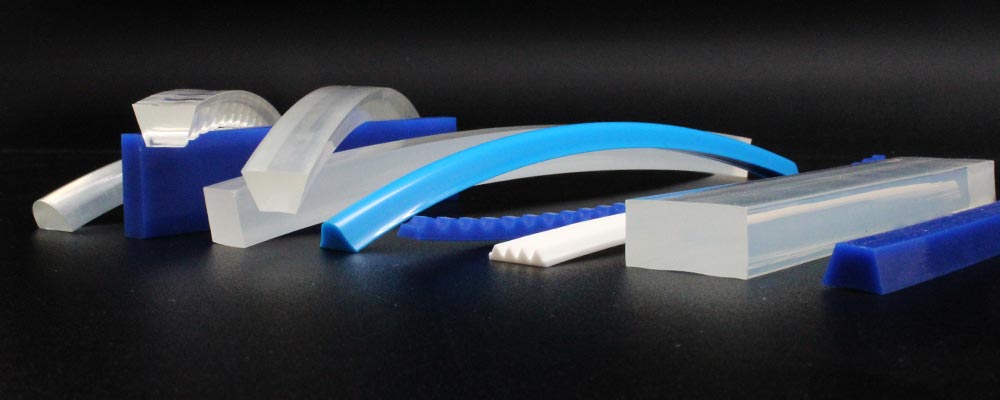

The trapezoidal V-guides are available in the standard toothed and non-toothed dimensions: 6x4mm (K6), 8x5mm (K8), 10x6mm (K10), 13x8mm (K13), 17x11mm (K17), 22×14 (K22). The dimensions 5x3mm, 13×6.5mm and 8×3.2mm are offered as special sizes.

In addition to square and rectangular profiles, semi-circular profiles are also available. For special belt guides we offer a longitudinal grooved profile.

BEHAbelt offers the shore hardnesses 65°A, 72°A, 76°A, 80°A and 84°A.

The PU70A safe quality is metal detectable.

All v-guides from Shore 76°A are FDA/EC compliant and thus certified for direct contact with food.

The perfect matching of the raw material types between the belt and the weld-on profile ensures an optimal connection (important especially for HF welds).

There are different ways of connecting the v-guides to the conveyor belts. In addition to HF (high-frequency) welding or hot air, cold cement or adhesive is also used. With the help of a guide roller/welding electrode, the v-guide is aligned and welded to the belt in the process.

Depending on the industry, the products to be conveyed and the specific system design, conveyor belts not only have to be cut to length and width, but also have to be assembled with cleats or edge trims. BEHAbelt offers a wide range of belt accessories for this purpose, homogeneously extruded from PU in different shore hardnesses.

Our conveyor belt accessories are made of the same raw materials as the conveyor belts to ensure the best possible weldability and a long service life in the application.

Of course, the accessories are also available FDA/EC/USDA compliant on request and with special properties, such as metal detectable, UV-C resistant or hydrolysis resistant.

Weld-on profiles are available from technical dealers or directly from BEHAbelt.

It is important to us to support you with our experience in selecting the suitable profile for your application.

BEHAbelt specialises in the production of extruded PU belt profiles and calendered PU belts. Thanks to our own toolmaking and modern, flexible production facilities, we can also manufacture customised solutions quickly and cost-effectively.