Twin-V-Belt

weldable Twin-V-Belts made of Polyurethane with or without reinforcement

request samples consultingweldable Twin-V-Belts made of Polyurethane with or without reinforcement

request samples consultingTwin-V-Belts made of polyurethane (PU) are an optimal solution for robust conveying or for spreading applications of product strands in the food industry.

Our portfolio includes different design variants, Shore hardness gradations and reinforced profiles.

PU75A skyblue smooth (30x8mm)

PU80A orange smooth,

Reinforced Polyester (21×8, 30x8mm)

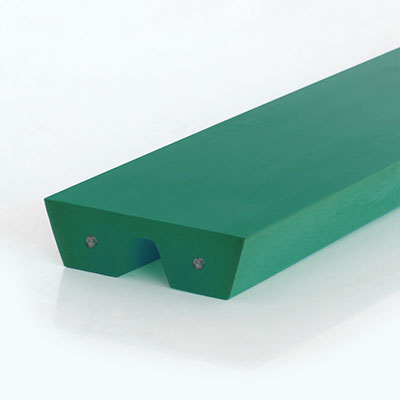

PU85A mint green smooth,

Reinforced Polyester (30x8mm)

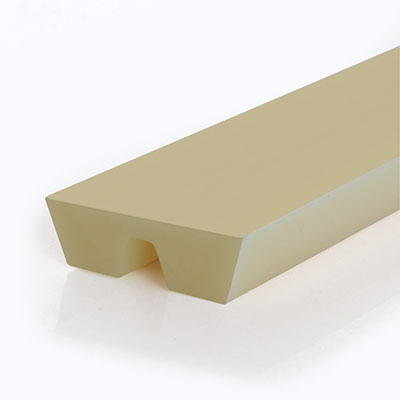

PU95A beige 3L smooth (24×6,8mm)

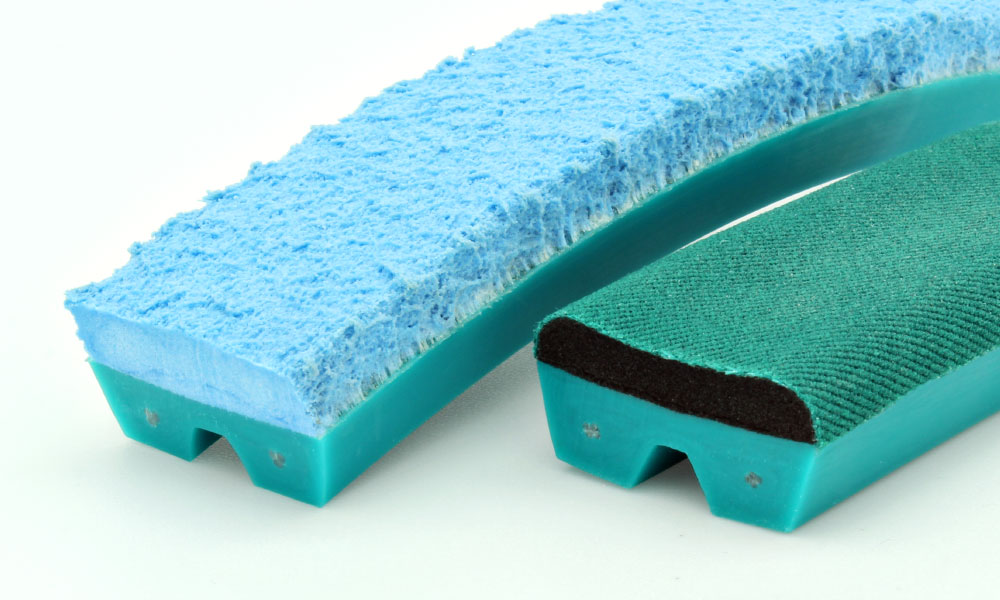

BEHAbelt offers different versions of Twin-V-Belts. Depending on the area of use and application, the profiles can be reinforced with so-called reinforcements (polyester, aramid, steel and weldable glass fibre PU). Thanks to different Shore hardness grades, optimum transmission and conveyor properties as well as a long service life are guaranteed.

BEHAbelt uses high-quality PU (polyurethane) materials for the production of Twin-V-belts, which guarantee optimum performance and a long service life in transmission and conveyor technology applications.

The geometry of the Twin-V-Belts is wide instead of high. On the one hand, this achieves mechanical strength and, at the same time, makes it possible to use smaller pulleys.

The wide contact surface can also be coated depending on the application.

The existing centre groove between the wedges is often used as an additional guide. Thus, a Twin-V-Belt has a similar function to a narrow conveyor belt that is guided by the welded-on V-guide.

Twin-V-Belts from BEHAbelt can be purchased by the metre, assembled end-to-end, delivered or welded on site.

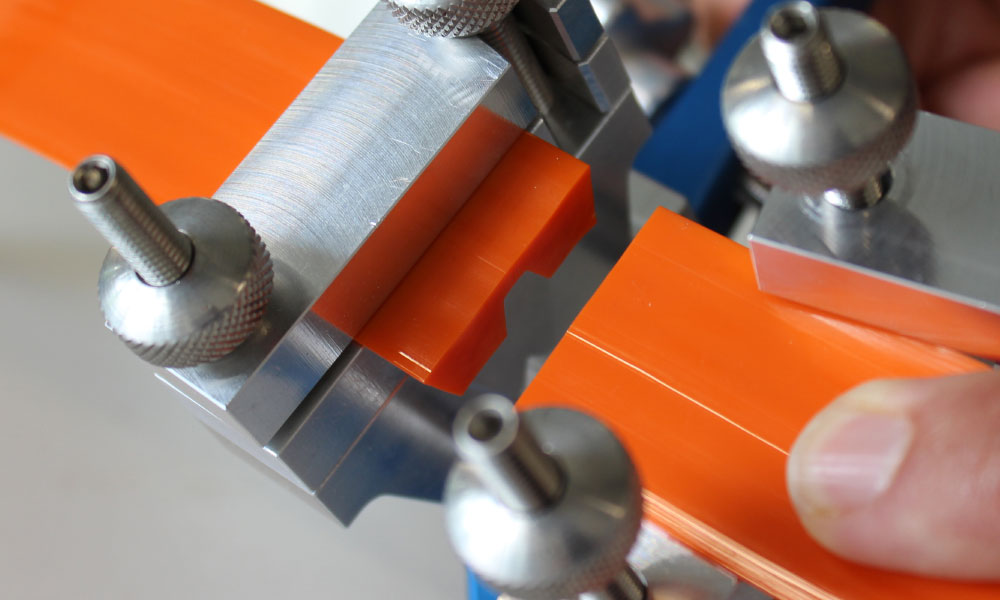

There are two ways of welding the profiles, either butt welding (for non-reinforced profiles) or overlap welding (for profiles with tension members).

Here the belt ends are cut by means of mitre cut or straight cut (e.g. with BEHAbelt AS02).

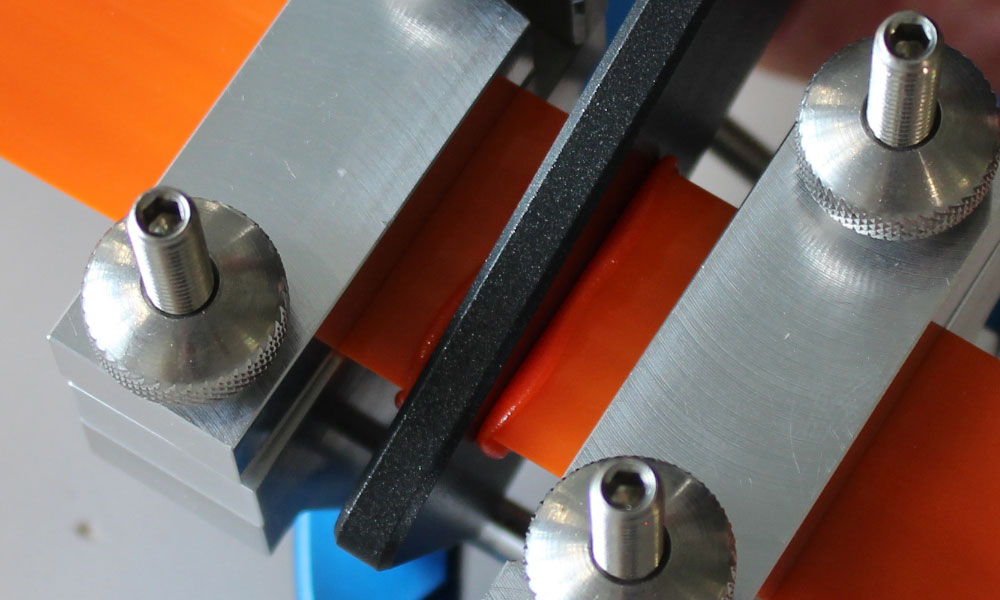

The guide clamp (e.g. FZ02/3) is used to align the two belt ends exactly.

For PU belts the welding temperature should be 290°C; for TPE belts 240°C. The welding paddle (e.g. EErgo) is held between the belt ends. Then the belt ends are pressed against the sides of the paddle by lateral pressure. The material melts. After the melting phase, the welding paddle is removed and the belt ends are pressed together with the guide clamp. After the cooling period, the belt is endlessly welded.

After the welding process and the cooling time, only the weld bead has to be removed using a side cutter (BEHAbelt SE02) or a sharp knife.

Twin-V-Belts are available from specialist technical dealers or directly from BEHAbelt.

It is important to us to support you with our experience in selecting the suitable belt profile for your application.

All Twin-V-Belts at a glance Request samplesDepending on the material to be conveyed, different belt profiles are required. BEHAbelt is specialised in the production of extruded thermoplastic belt profiles. Thanks to our own toolmaking and modern, flexible production facilities, we can also produce customised profiles quickly and cost-effectively.