The range of different application types in intralogistics is very extensive. In order that the individual processes can be coordinated in the best possible way, BEHAbelt offers versatile solutions for the requirements of material handling. Our product solutions reach from classic round and V-belts to elastic monolithic conveyor belts. The suitable welding technology allows you to minimize downtimes quickly and cost-savingly, even on site.

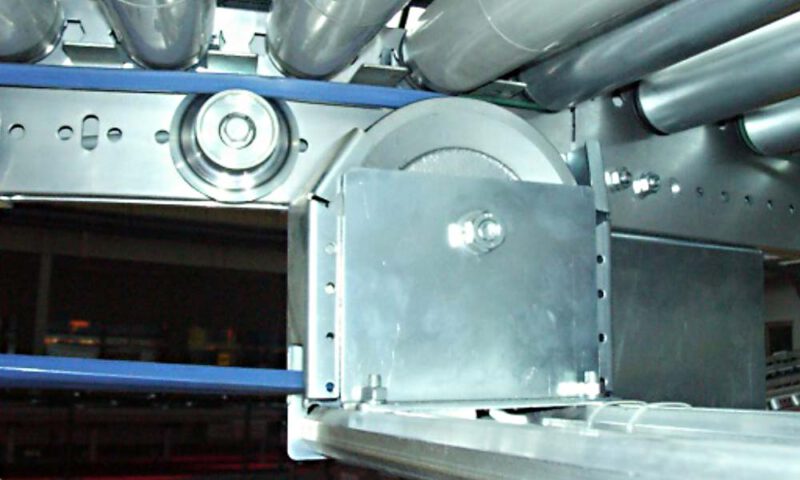

Roller Conveyor

Check Weigher

Ascending conveyor

Inclined conveyor

Labelling systems

Cross conveyors

Packaging machines

Conveyor lines

Curved conveyors

Inward and outward transfer

Weighing technology

Sorting conveyors and many more

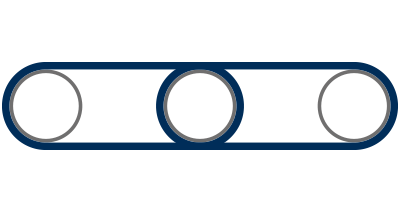

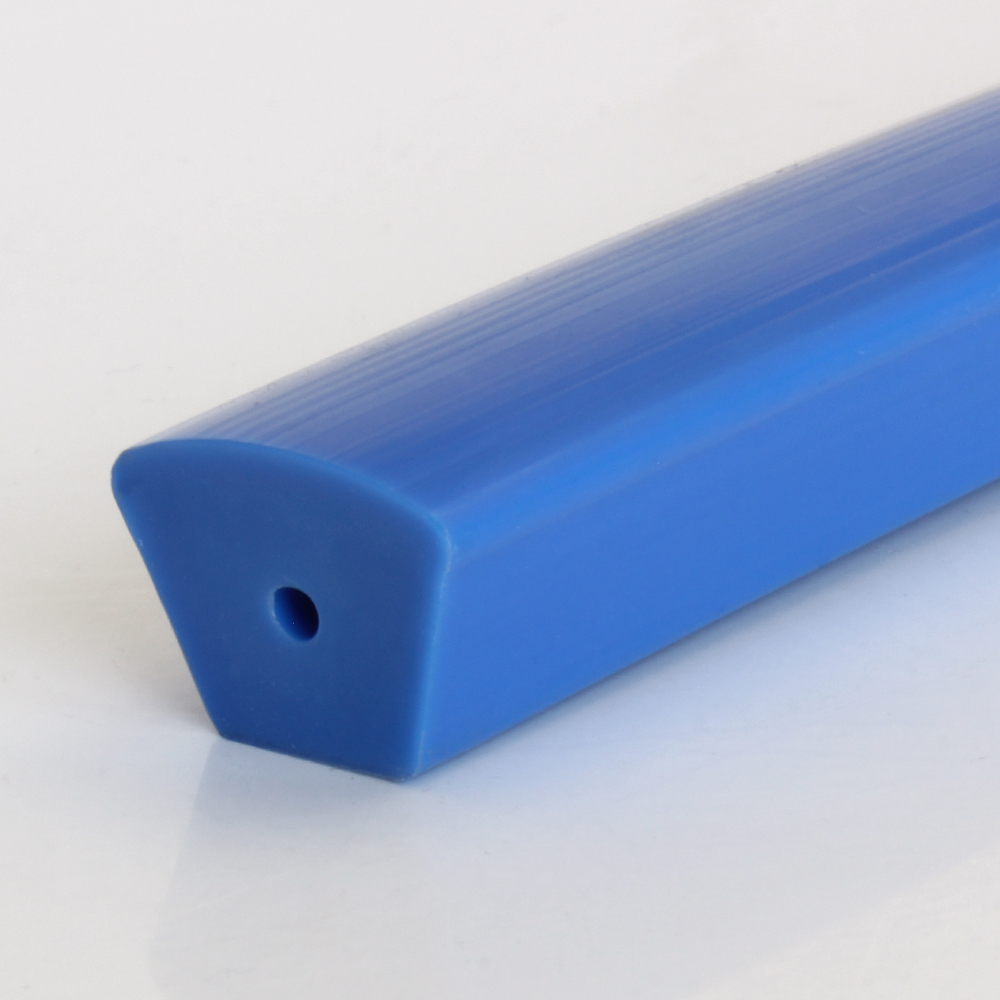

Belt profiles for roller conveyors /

Tangential drive

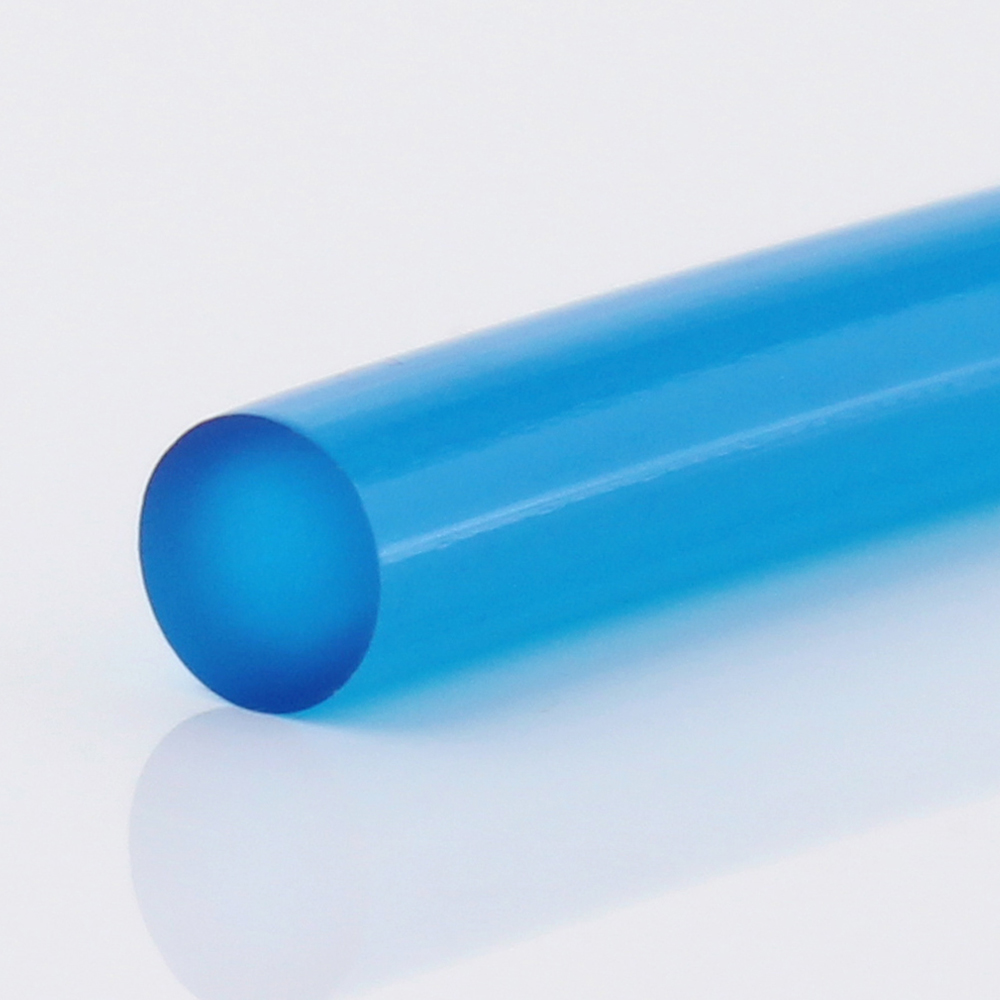

In the logistics industry, roller conveyors have a prevalent position; they can be found in almost every process area. This includes our BEHAbelt tangential belt Bluepower as well as our special low stretch material compound PUplus, which are designed for dimensional stability and high load and torque absorption.

For roller-to-roller drives we also offer round belts as well as a unique Poly-V solution, which can also be joined quickly and easily on site to keep downtime to a minimum.

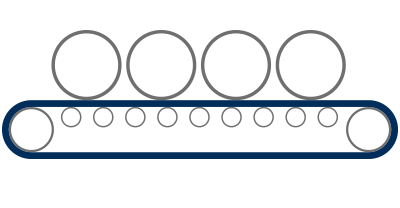

Monolithic conveyor belts for conveyor lines

Even basic conveying functions require numerous different belt properties, for different materials to be conveyed, conveying speeds, deflection cards, stop & go and accumulation operation as well as other operating conditions BEHAbelt supplies optimally designed product solutions.

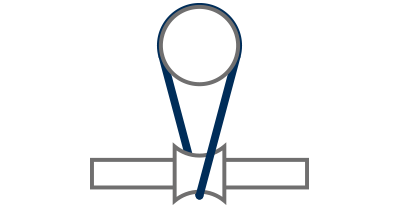

Crossed drive / Central drive shaft with Round belts or Flat belts

To avoid long downtimes, the use of weldable elastic belt profiles offers considerable advantages. With our professional welding technology, you can replace roller conveyor belts quickly and easily.

As an alternative, there are two types with mechanical quick-connections: hook belts or hollow round belts. This end connection is made without welding and therefore does not require trained worker.

In addition to round belts, weldable flat belts with a hardness of Shore 84°A or higher are also used in crossed drives.

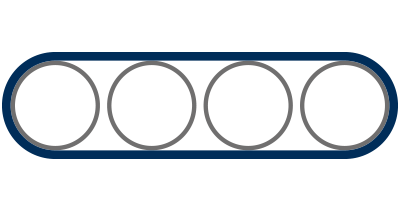

Optimise inclined conveyors with 2-component conveyor belts

Conveyed goods can be transported at an angle even with smooth belt surfaces. The conveying angles that can be realized here depend on the nature of the material to be conveyed, the coating on the carrying side and the external influences such as dust, humidity, etc. For larger conveying angles and the conveying of small parts and bulk materials, BEHAbelt supplies structured or cross-profiled conveyor belts.

Elastic belts in intralogistics reduce the costs of system design, as tensioning stations are largely unnecessary. Depending on the material to be conveyed or the type of conveyor (e.g. accumulation or inclined conveyor), a wide variety of belt types are required. With BEHAbelt‘s new 2-component design, 2 different degrees of shore hardness can be combined in one belt. If a belt for inclined conveying is required, the conveying side can have high grip, while the running side has low friction.

Poly-V (PJ) for Roller-to-Roller

For roller-to-roller conveyors, we also offer round belts as well as a unique Poly-V solution that can also be quickly and easily joined on site to minimise time loss.

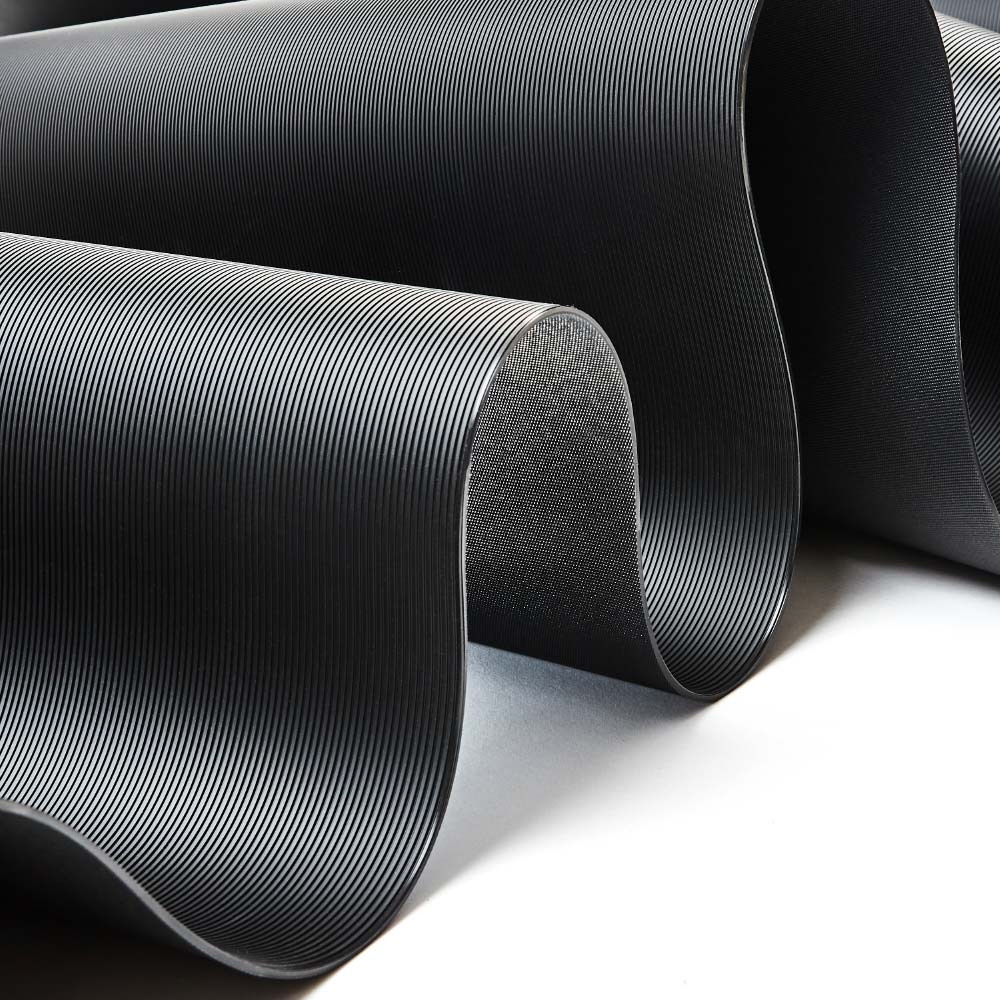

Thin conveyor belts for cross belt conveyors

Crossbelt sorters generally require very thin and flexible belts whose surfaces have high coefficients of friction. High coefficients of friction on the carrying side guarantee precise transfer to the sorter. In cross belt sorters, the high acceleration requires extremely good friction coefficients of the belt surface. BEHAbelt offers belts with a thickness of 0.9 mm and more.

Our motto is “smart conveying”. BEHAbelt is a specialist and provides detailed advice.

It is important to us to support you with our experience in selecting the most suitable belt or conveyor for your application. The resulting know-how from many applications shows us that there is potential for optimisation in most processes.

Request samples get advice download brochureOverview of profile belts and conveyor belts for intralogistics / material handling

For the manufacturing of belt profiles BEHAbelt works with high quality PU and TPE materials which guarantee an optimal performance and a long service life in conveyor technology and drive applications. On the one hand they are resistant to oil, grease or chemical agents and on the other hand they are resistant to hydrolysis.

The extruded belts are available in various Shore hardnesses and diameters. Depending on the requirements, they are reinforced with a tensile member and thus increase the tensile load and tensile strength.

Both PU and TPE belt profiles are easy to weld. BEHAbelt delivers the belts either endlessly welded to your desired length or the belts can be welded independently on site.

Poly-V (PJ) V-ribbed belts

Elastic BEHAbelt PUplus V-ribbed belts PJ offer a powerful power transmission for linear and curved conveyors in the light load range up to approx. 50 kg. The special material mixture PUplus provides an optimal compromise between tensile strength and elasticity. Each length can be produced independently on site with a welding paddle and guide clamp. Thanks to the elasticity, installation and belt replacement are simple and time-saving. Due to the in-house fabrication, BEHAbelt can also deliver the profiles endlessly welded.

Monolithic Conveyor Belts

are extruded homogeneously and do not consist of several layers that are connected to each other. Layer separation or the detachment of coating particles are therefore impossible.

Special features like antistatic dissipation, UV resistance, cold flexibility or hydrolysis resistance can be added by using additives in the manufacturing process.

Belt constructions of BEHAbelt can be manufactured in one or two layers (2C-technology) in order to combine different product requirements on the top and bottom side of the conveyor belt optimally. For example, when designing a belt for an inclined conveyor, the transport side can have more grip, but the running side can have good sliding properties.

Welding tools for belt profiles and conveyor belts

For belt profiles:

Friction welding machine RS02

Butt welding in seconds with the unique

unique RS02 friction welding machine for PU profiles.

For Belt profiles and Flat belt strips: Paddle welding tools EErgo 60/90

The BEHAbelt EErgo 60 and 90 welding paddles have been specially developed for joining PU and TPE profiles or flat strips.

For Conveyor belts:

Welding unit: HS400 & HS800

With this welding unit, conveyor belts can be joined on site with process reliability by means of butt welding. Up to 800mm width.