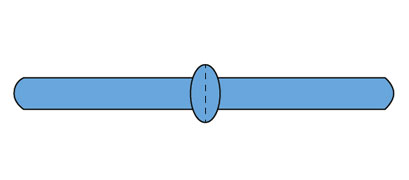

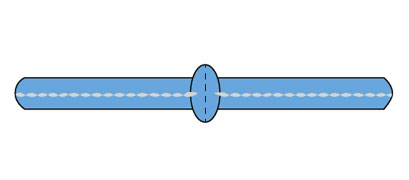

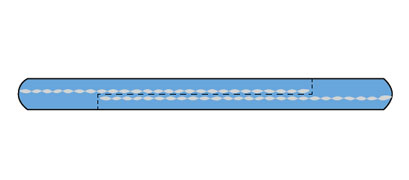

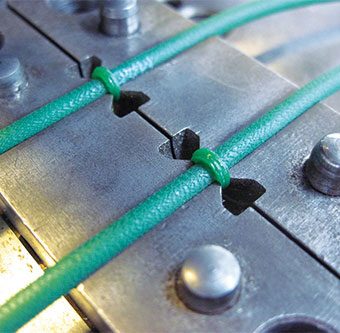

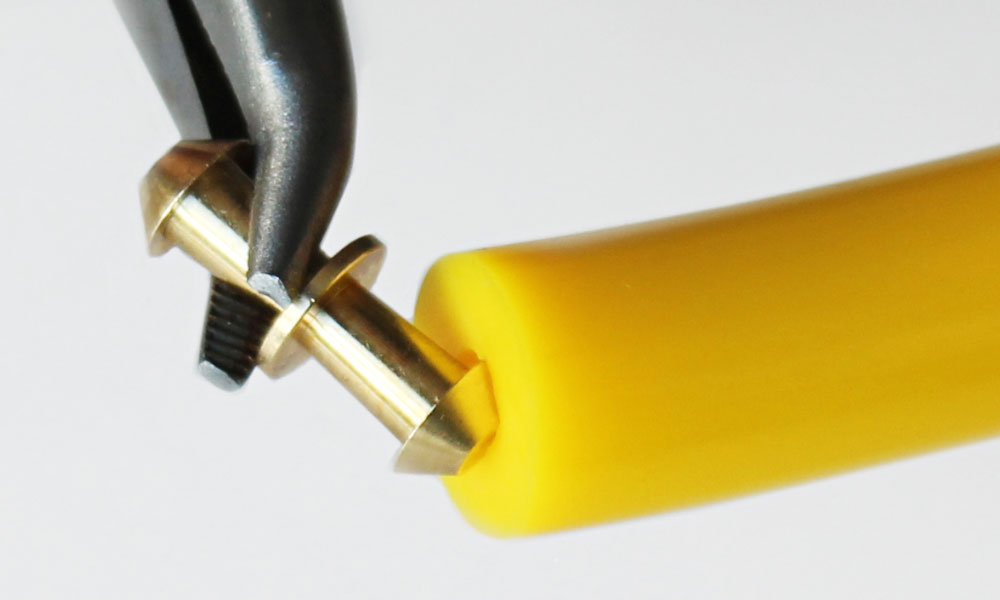

Fitting connectors for hollow round belts

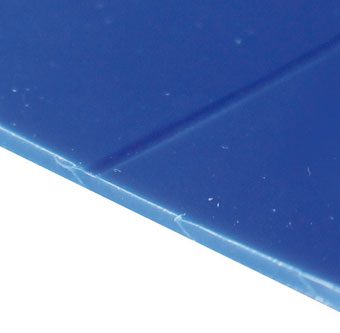

Hollow round belts should be welded just like solid belts. In the case of breakdown, fitting connectors can be used for a quick repair, until the belt can be welded once again.

more information…

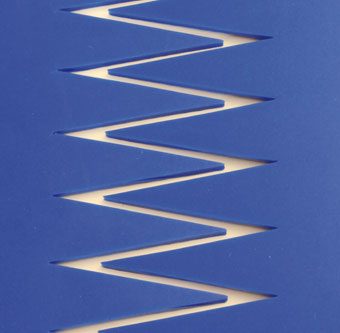

Hakenverbindung

Twisted PU round belts, also called “quick connect belts”, are the perfect solution for roller conveyor systems where more than one belt is sitting on a shaft (called vertical drive).

more information…