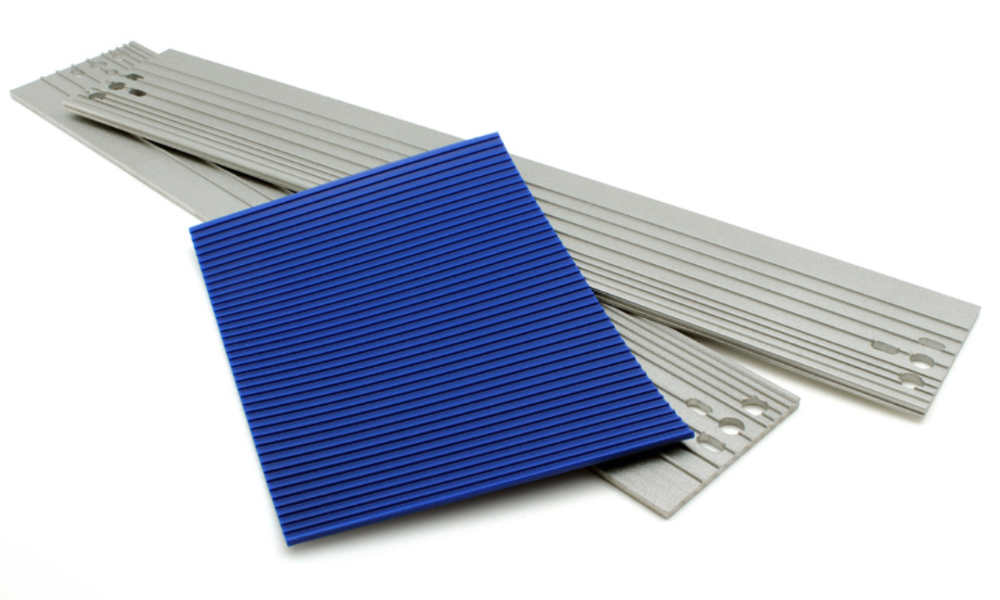

AT5 Conveyor belts

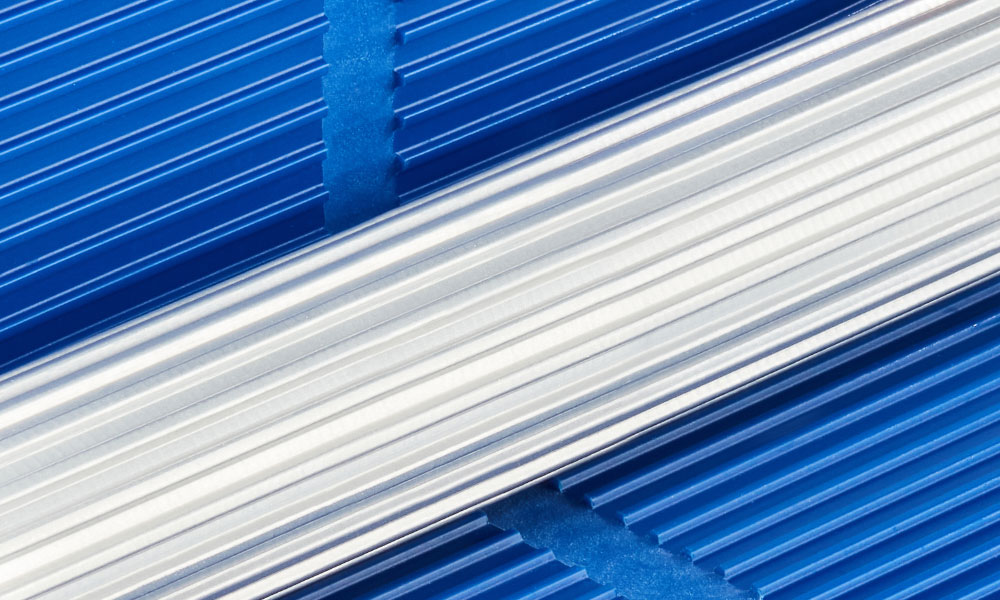

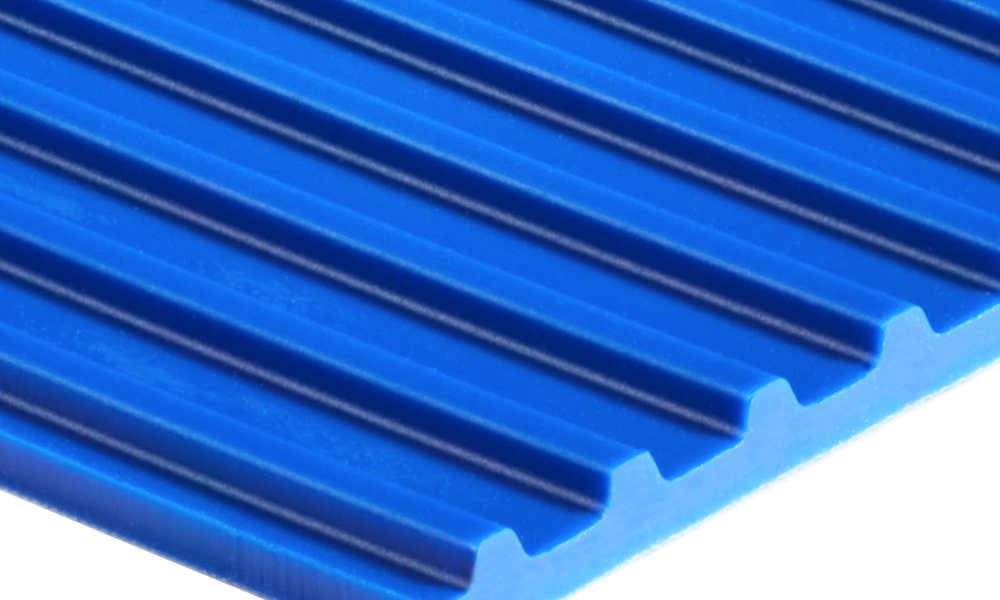

Slip-free monolithic conveyor belts for positive drive

Technical advice Request samples

Slip-free monolithic conveyor belts for positive drive

Technical advice Request samplesThe positive driven AT5 conveyor belts from BEHAbelt enable slip-free traction, even with the smallest pulley diameters of only Ø 18 mm. This means that even conveyor sections with the smallest transfers can now be utilized with a slip-free belt solution.

In combination with a maximum belt width of up to 700 mm, the new product series from BEHAbelt represents a new product solution which once again shifts the previous limits of the possible applications of positive-driven belt solutions on the market.

This makes the positive driven conveyors perfect for applications that require precise timing, positioning and reversing. The low preload minimises the bearing load and thus reduces the energy requirement as well as the maintenance effort.

BEHAbelt already offers a wide variety of functional belt surfaces in this product category. Due to our close contact with machinery engineers and end users, we have continuously expanded and adapted our belt surfaces to optimally convey greasy, moist, dry or frozen products.

All belts are available in usable widths of up to 700 mm and are monolithically manufactured in a 2-component process.

Let us know if you need an alternative based on your requirement.

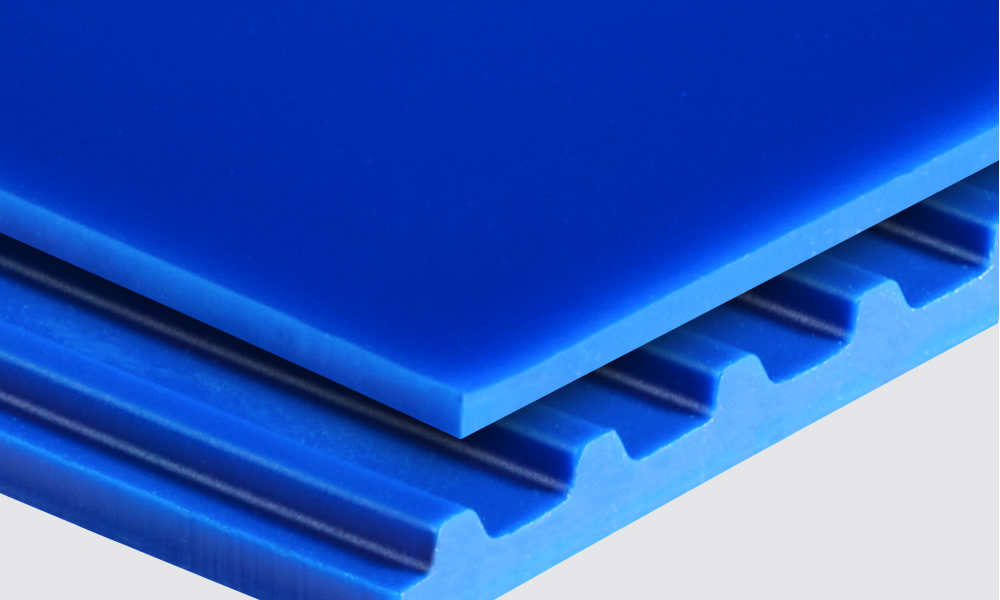

Features: Very good grip. Very good cleanability. Excellent grip.

Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 18 mm

Tooth height/Belt thickness (total): 1,2mm/3,0mm

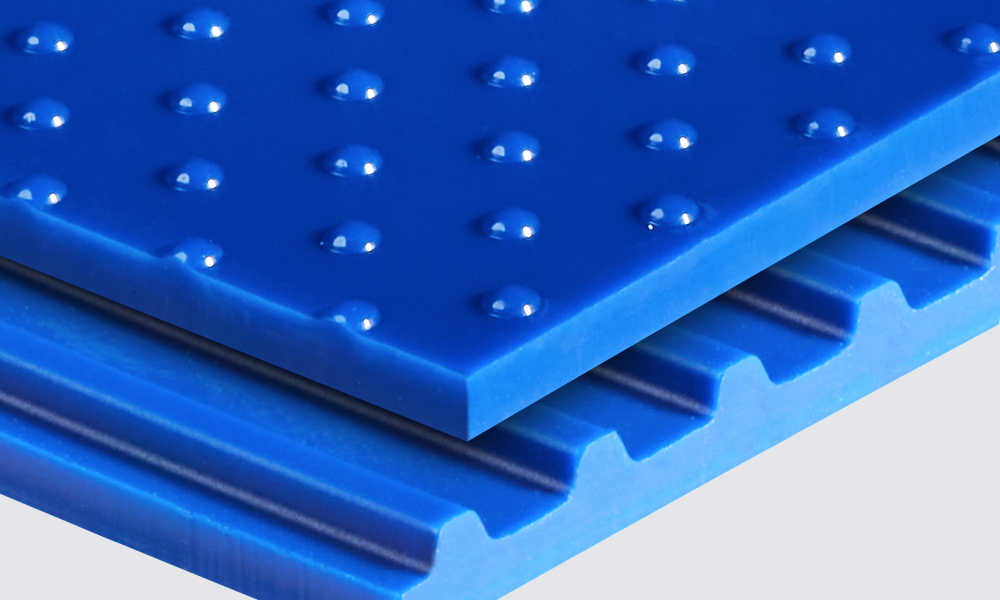

Features: Good release properties. Universal application possibilities. Very good grip.

Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 18 mm

Tooth height/Belt thickness (total): 1,2mm/3,0mm

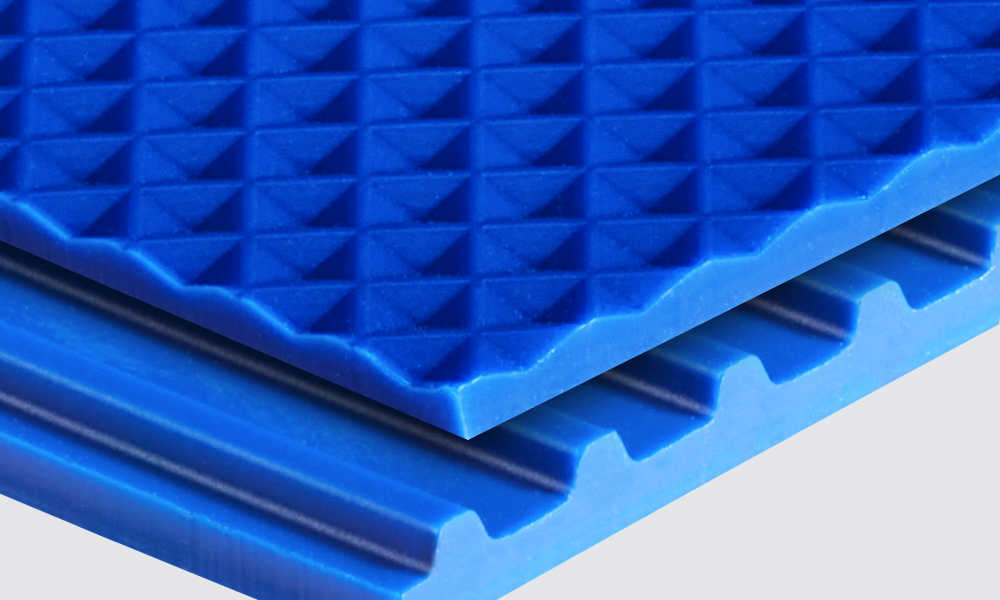

Features: Very good release properties. Universal application possibilities. Good grip.

Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 18 mm

Tooth height/Belt thickness (total): 1,2mm/3,0mm

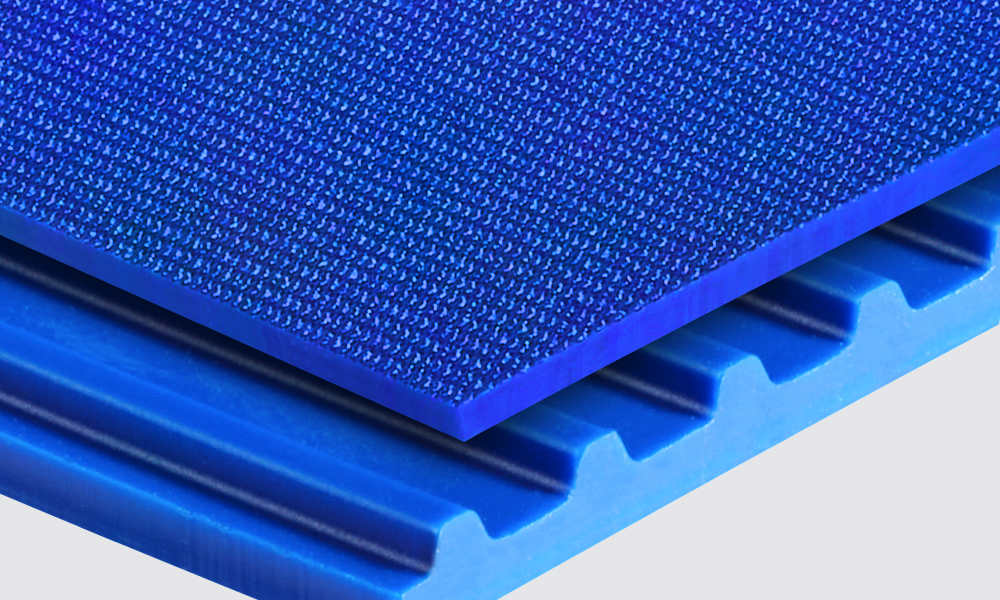

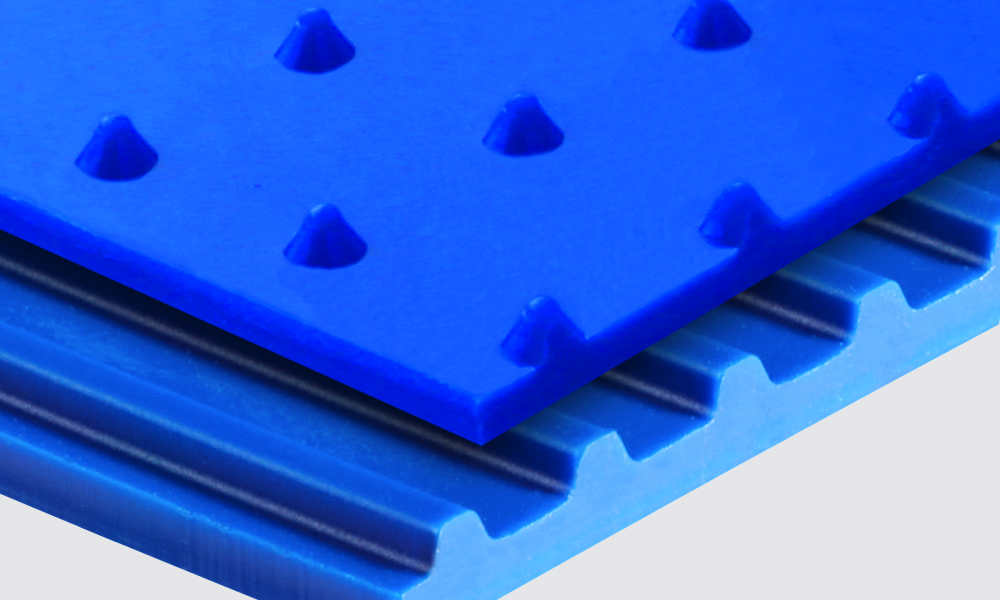

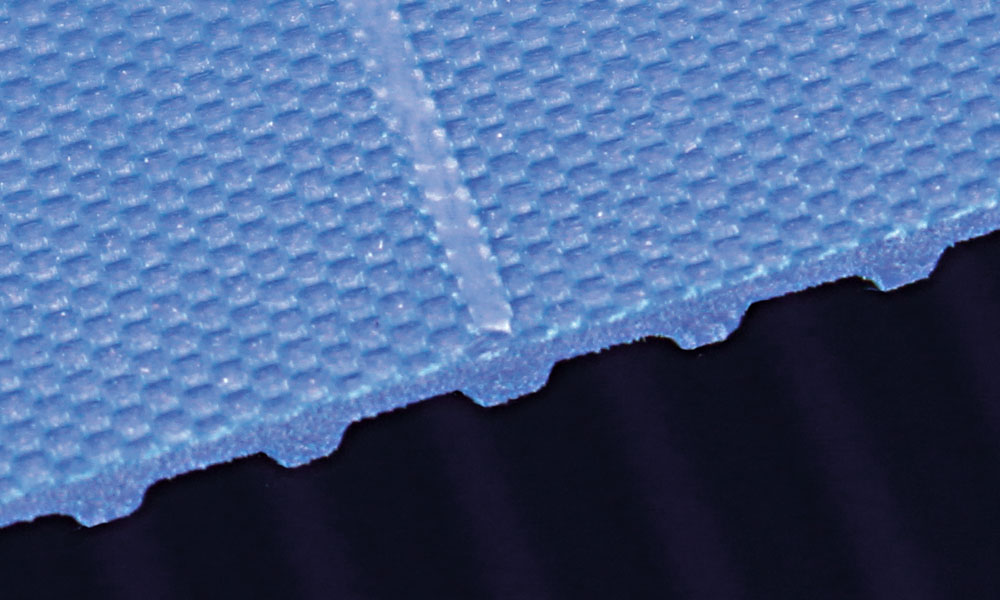

Features: Very good release properties combined with good grip and very good cleanability. Very good grip.

Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 25 mm

Tooth height/Belt thickness (total): 1,2mm/3,2mm (+ Nubs 0,5mm)

Features: Especially suitable for greasy and frozen products. Excellent grip. Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 25 mm

Tooth height/Belt thickness (total): 1,2mm/3,0mm (+ Spikes 1,5mm)

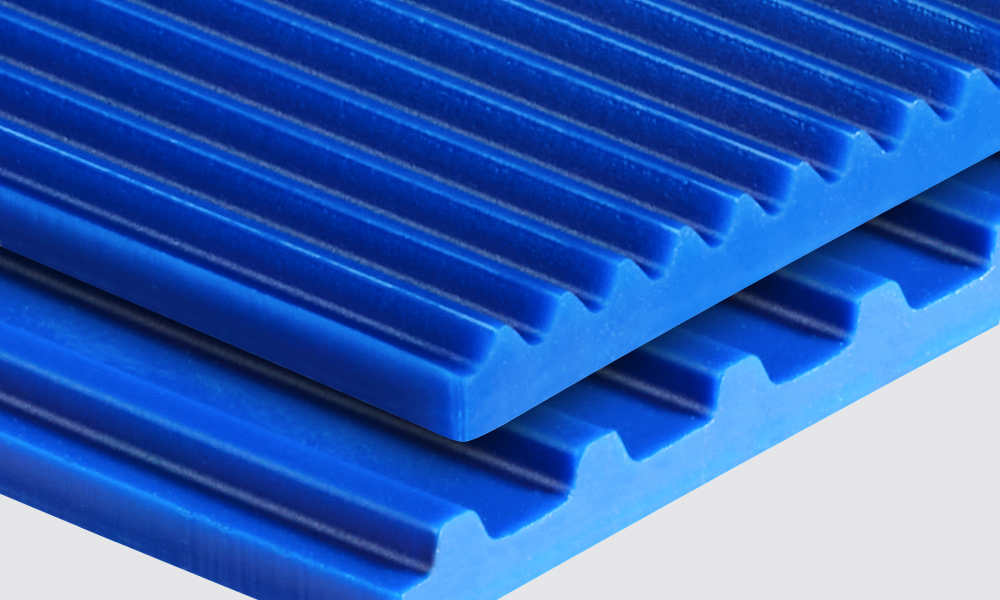

Features: Good release for dough products. Self-cleaning. For sticky and greasy products. Very good grip.

Hardness (Shore): 72 A / 84 A

Min. pulley diameter Ø: 28mm

Tooth height/Belt thickness (total): 1,2mm/3,8mm

The completely monolithic construction of the conveyor belts without aramid strands or fabric layers and without coiling noses offers an optimal hygienic belt design which meets the highest requirements in the food industry according to HACCP and offers a preventive hygienic machine design.

Thanks to a careful selection of raw materials for direct food contact, the belt solutions offer very good microbial, hydrolysis and chemical resistance.

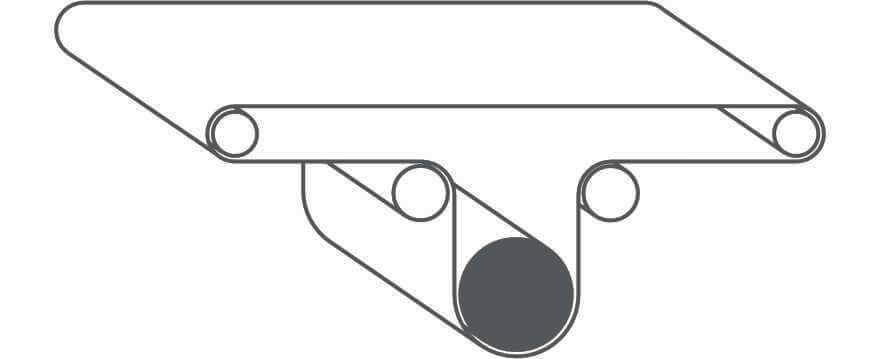

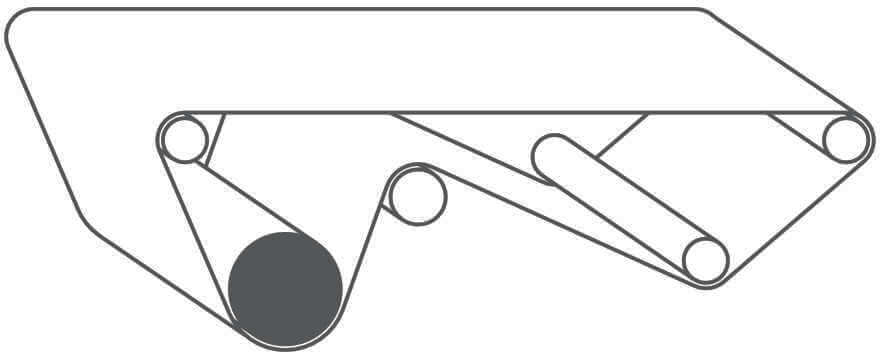

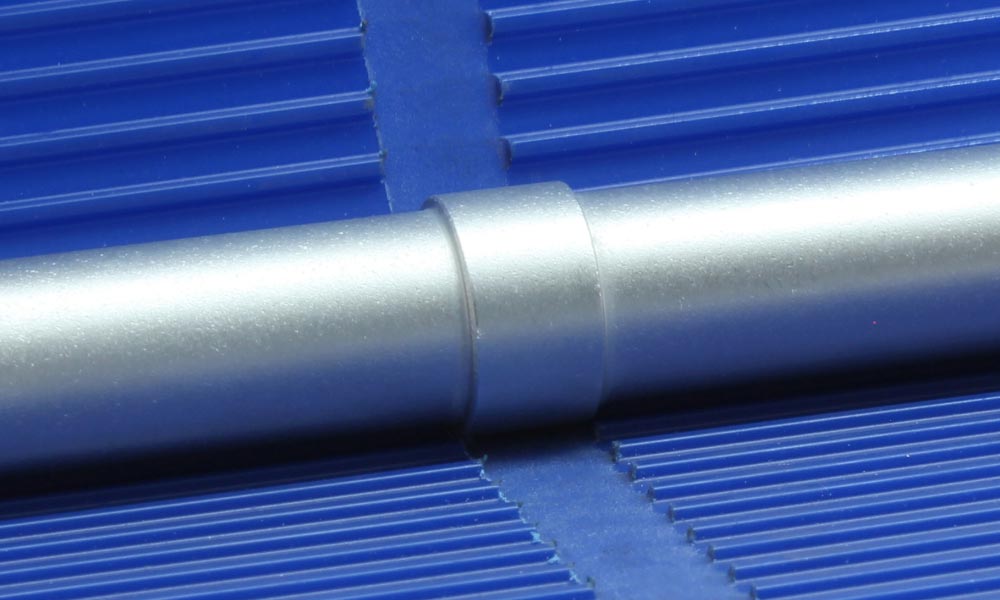

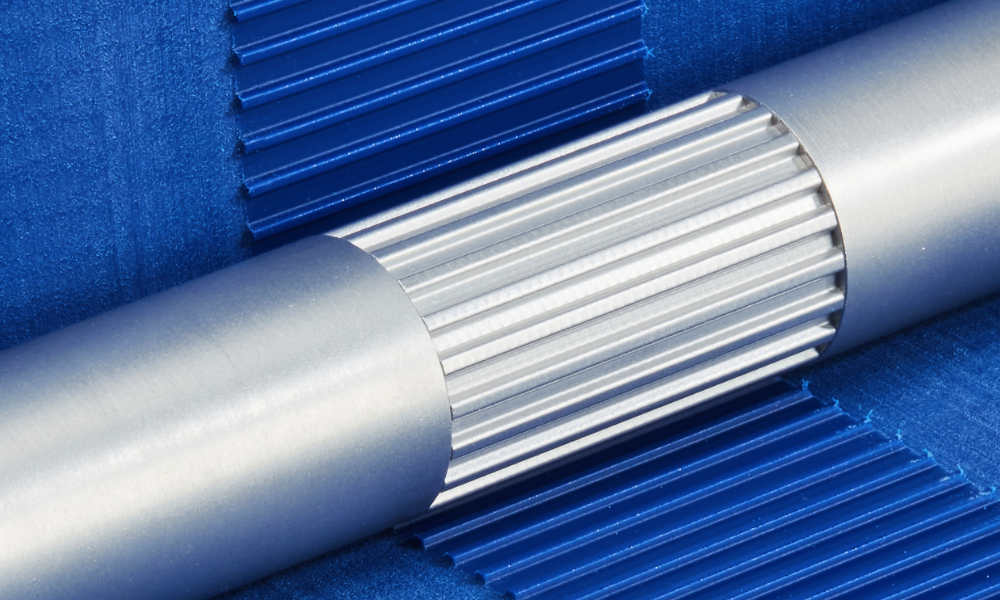

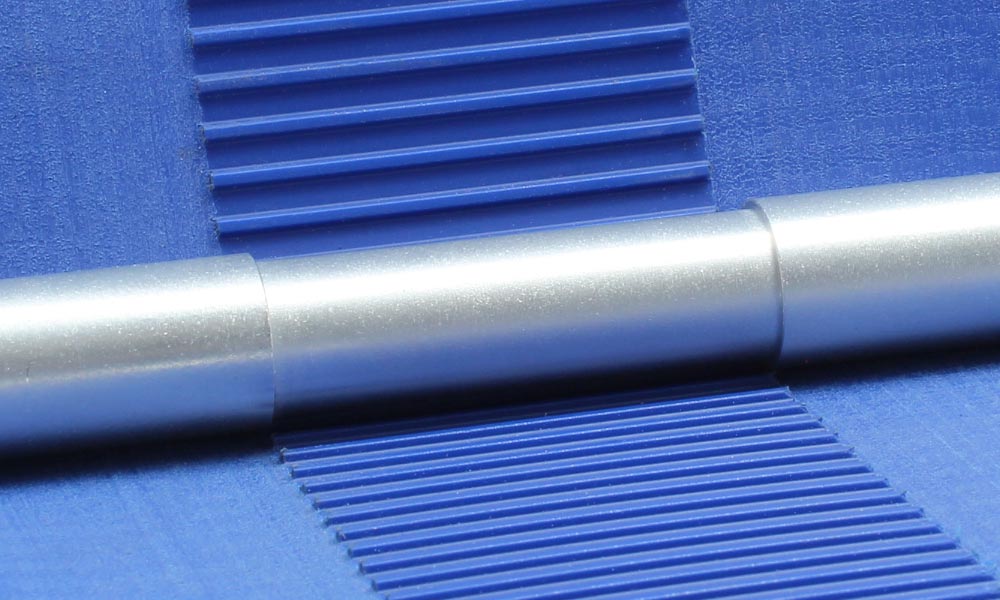

The AT5 belts can be used in different belt drive concepts. While the drive drum is mostly effective using the AT5 or T5, pulleys are often designed cylindrically smooth with a suitable guide shape.

Precisely because of the flexibility of the slip-free belts, very small pulleys can be designed at the drive and idler pulley, which, in addition to cost savings or conversion of the motor and drive concepts, may also require less installation space and allow better accessibility to the system parts.

Head drive

Centre drive

Shifted centre drive

The interaction of the AT5 drive with the optimum belt guidance ensures tracking stability and slip-free drive.

Precisely because of the flexibility of the slip-free belts, very small pulleys can be designed at the drive and idler pulley, which, in addition to cost savings or conversion of the motor and drive concepts, may also require less installation space and allow better accessibility to the system parts.

Drive with guiding groove

Guide with guiding groove

Drive with guiding bar

Guide with guiding bar

The slip-free belts from BEHAbelt allow a process-safe application, thanks to a standardised pretension recommendation for all belt widths and belt designs. The low pretension of only 1.5% +0.5% enables easy installation and also reduces the bearing load and heat development in rolling nose bar (usually made of plastic).

For the operation of the elastic belts we recommend to use AT5 pulleys to allow a maximum range of application; T5 pulleys can also be used under certain conditions.

Thanks to the belt width of up to 700 mm, multiple belt strands designs can be replaced by one belt, which represents hygienic improvement and simplifies the design of the systems.

Particularly for light and medium loads, timing belt solutions can be replaced, which were previously used as “conveyor belts”. Consult your BEHA representative for assistance.

The following videos show the non-slip AT5 belts installed in conveyors.

Due to the elastic monolithic belt construction, the use of the belts is essentially recommended for small and medium weights. Wherever precise timing, positioning and reversing is required, this belt solution is an great alternative and product solution.

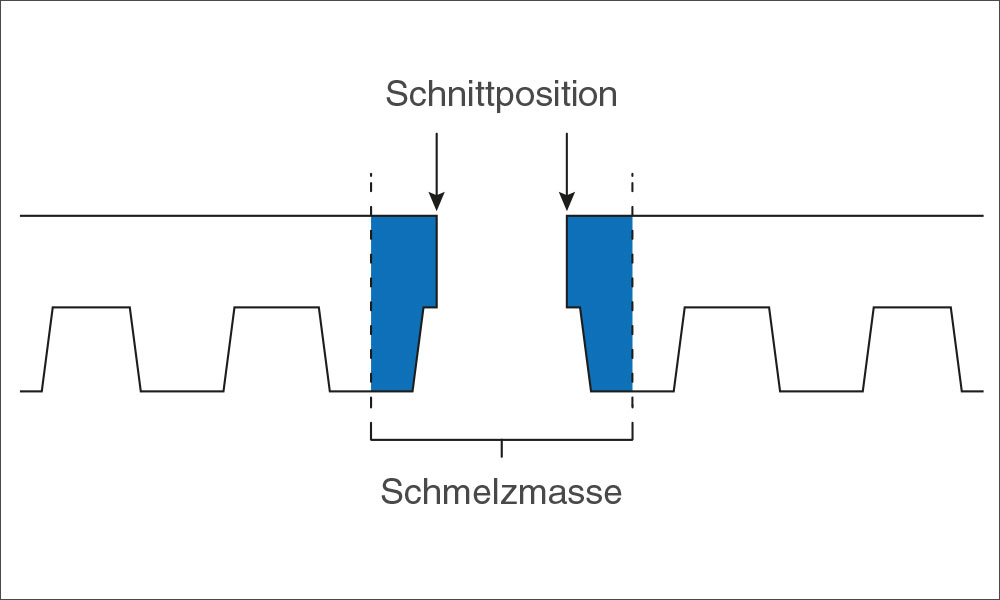

Simple butt welding is enough: Elastic monolithic PU conveyor belts from BEHAbelt offer new fabrica- tion possibilities. Due to the lack of traction layers joining by finger welding is no longer necessary, as the monolithic belt has a homogeneous design – even in the weld seam.

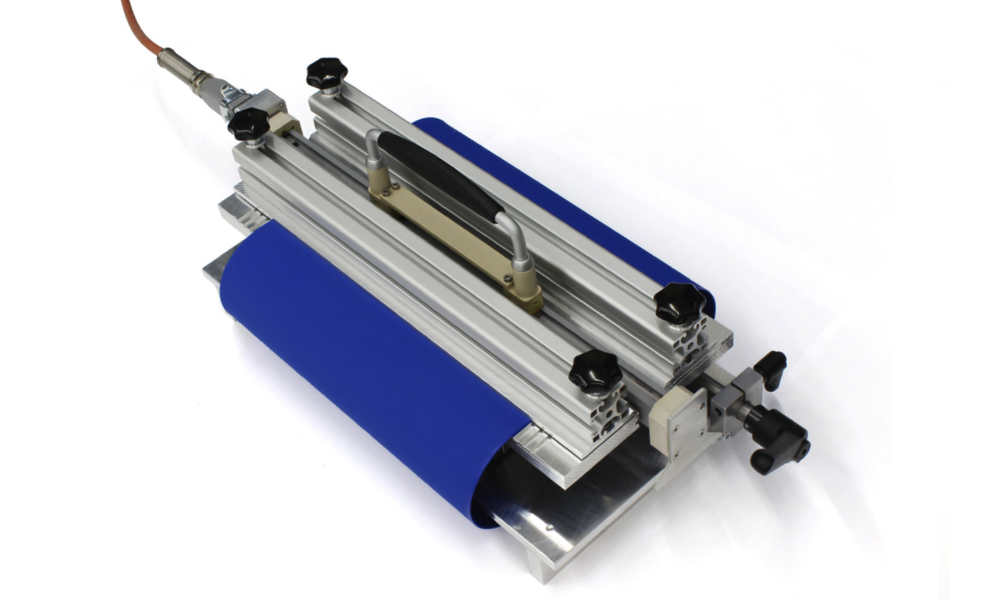

Welding device HS400 & 800:: The welding device HS from BEHAbelt is a simple, handy, reliable and cost-effective tool for butt splicing of monolithic belts (up to 800mm width).

Precision: The adapter plates, specially designed for the AT5 pitch, ensure precise positioning and clamping of the belt ends to be welded.

BEHAbelt Welding device HS400 & 800

Special adapter plates for AT5

AT5 conveyor belts are available from specialist technical distributors or directly from BEHAbelt.

It is important to us to support you with our experience in selecting the suitable conveyor belt for your application.

Technical advice Request samplesBEHAbelt specialises in the production of extruded PU belt profiles and calendered PU belts. Thanks to our own in-house tool construction and modern, flexible production facilities, we can also manufacture customised solutions quickly and cost-effectively.