Connection methods for belt profiles

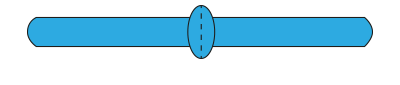

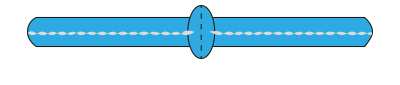

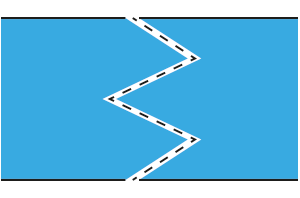

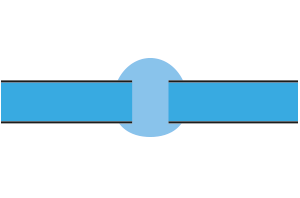

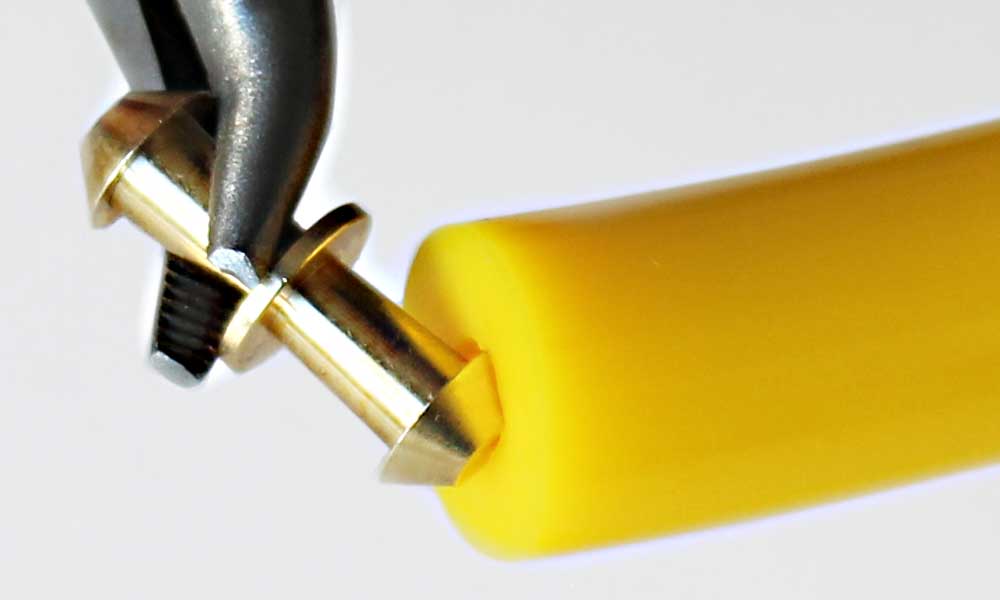

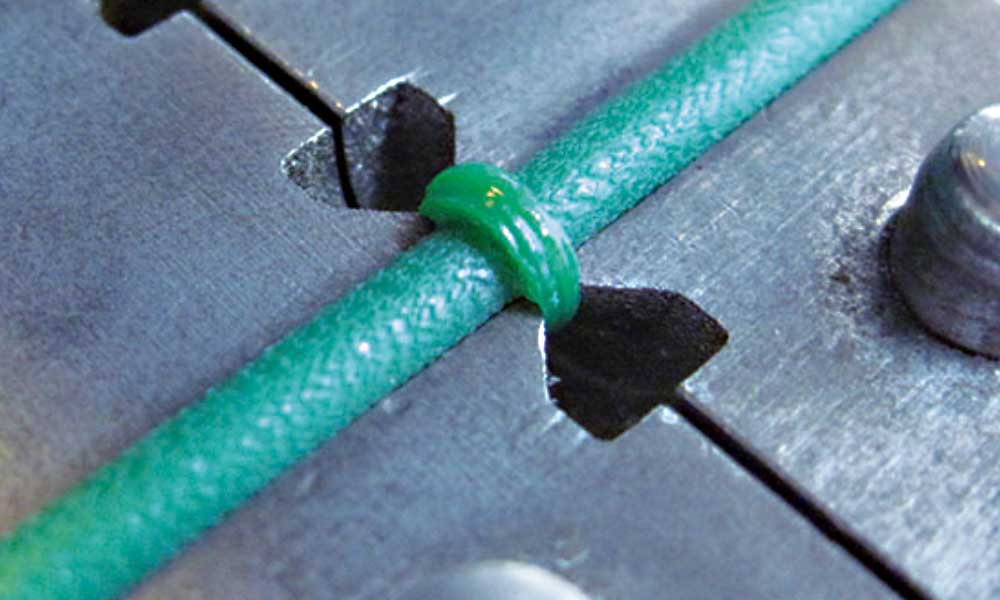

Regardless of whether you are using unreinforced belts or reinforced belts, we distinguish the following connection methods: butt and overlap welding.

Two connection methods can be used on profiles with reinforcement. Butt welding to reduce elongation without changing the belt strength. Overlap welding to reduce elongation and increase the belt strength.

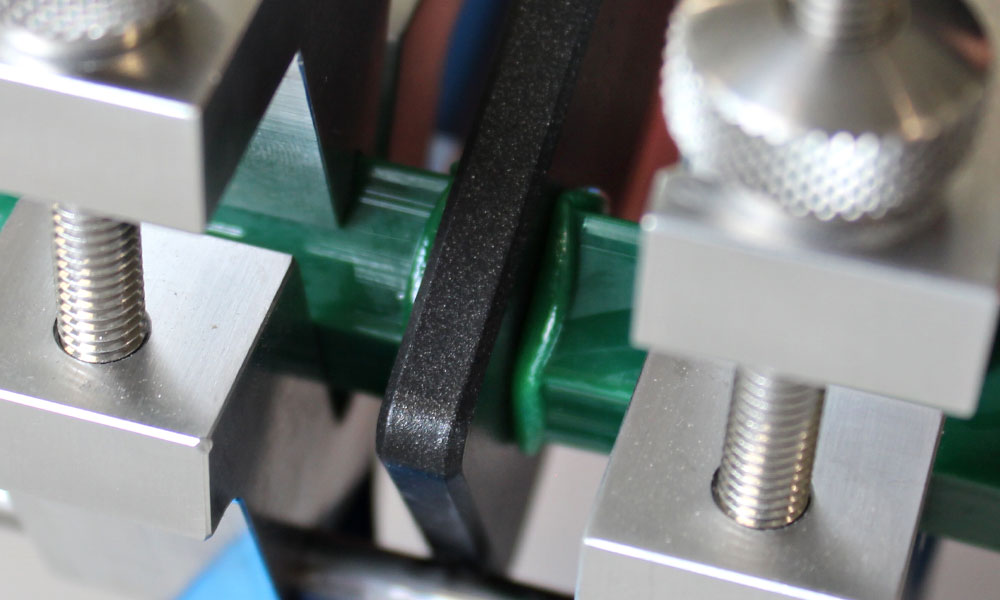

Thermowelding types for conveyor belts

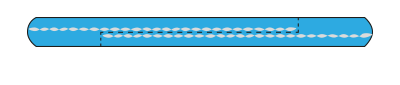

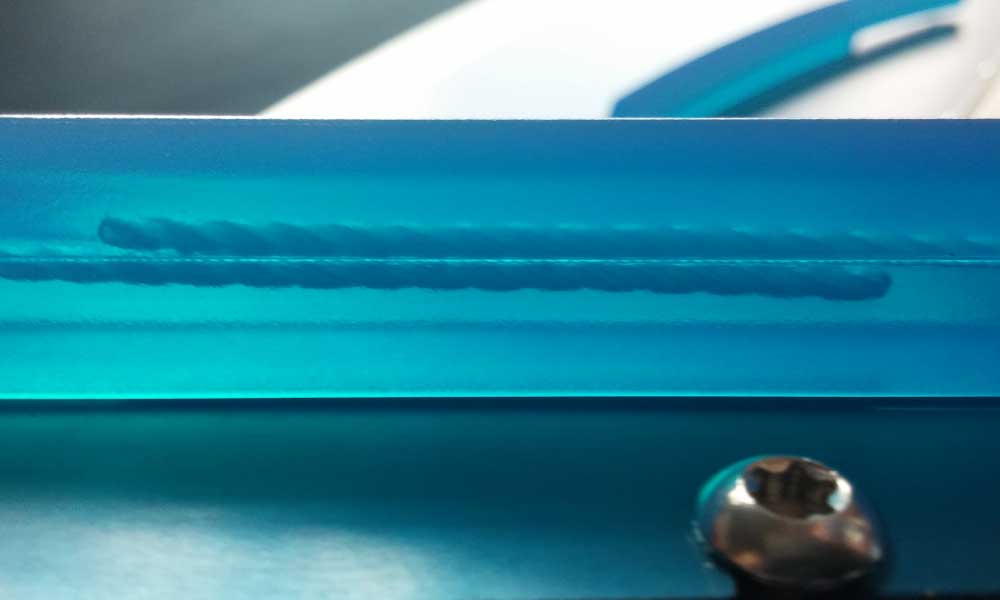

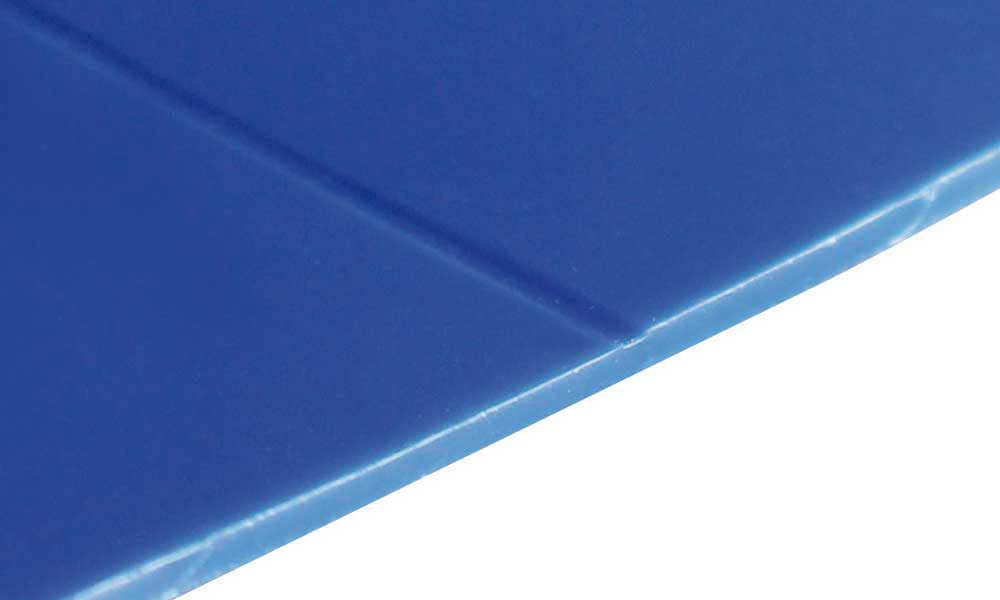

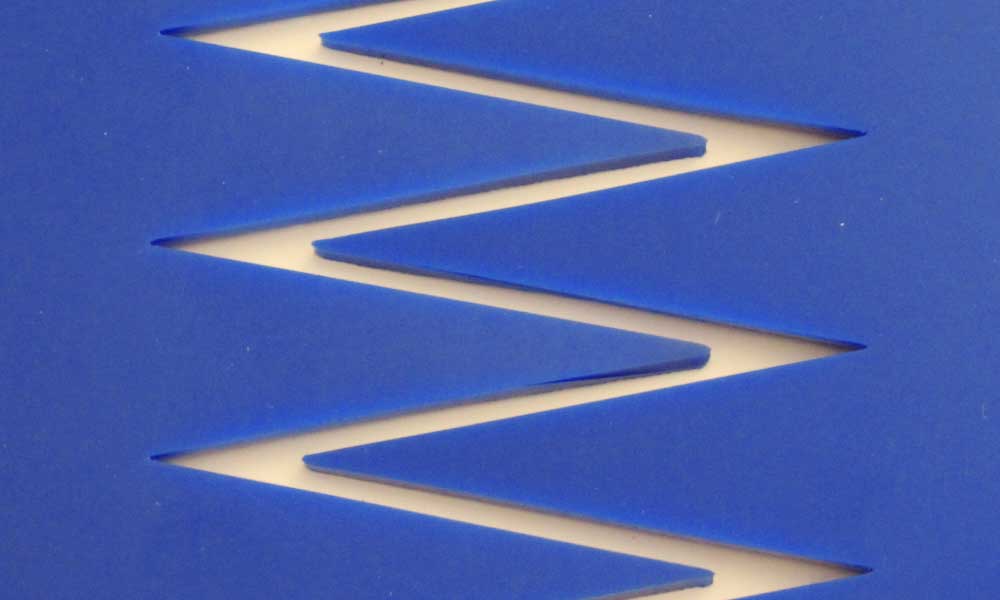

Elastic monolithic PU conveyor belts from BEHAbelt offer new possibilities for endless joining due to the full PU belt construction. Due to the belt design without traction-layer, a connection by finger welding is no longer necessary, as the monolithic belt is a homogeneous belt design in itself – even in the joining area.

A preferably homogeneous design of the joint is a quality criterion both functionally and with regard to the elastic elongation behaviour of the monolithic strip.

In principle, this potentially “inhomogeneous“ area should be as narrow as possible, since the relatively large pretensioning force applied to monolithic tapes of 0.5…4% inhomogeneity in the belt is very quickly visible in the tensioned state.

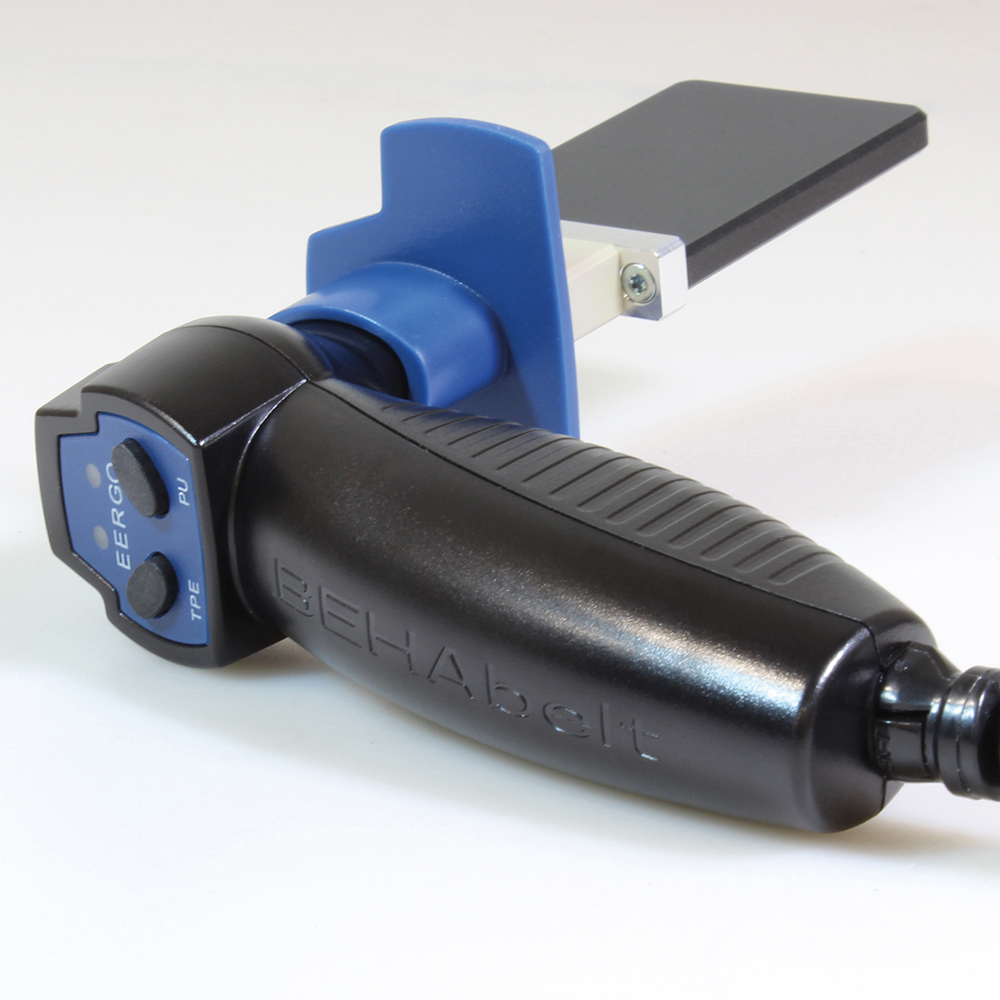

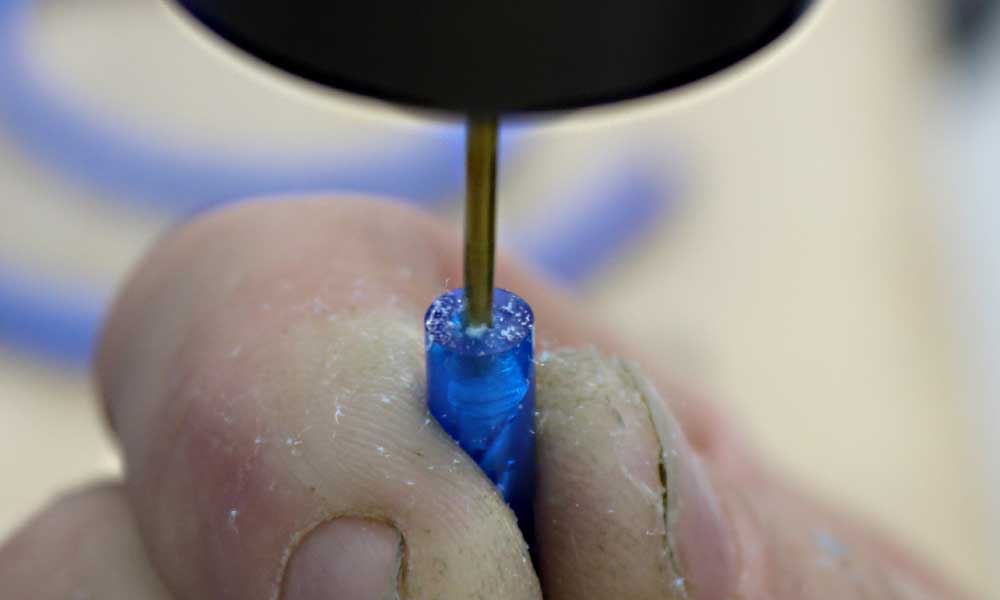

Videos explaining the thermowelding techniques

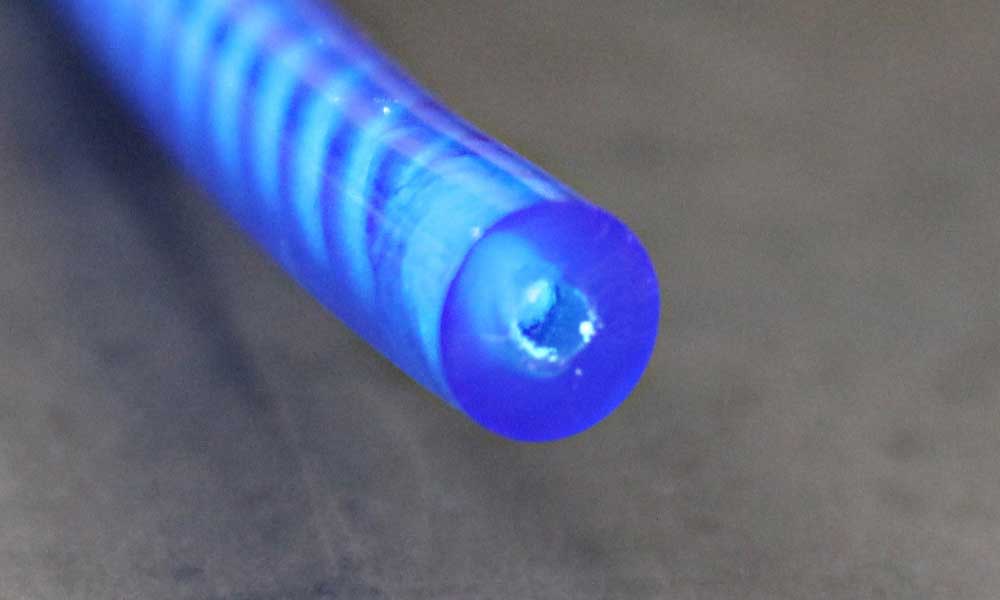

In the videos listed below, we show you in detail how professional thermowelds are e.g. with round belts or bands. You are also welcome to visit our YouTube channel here or subscribe. We always post our latest videos here.

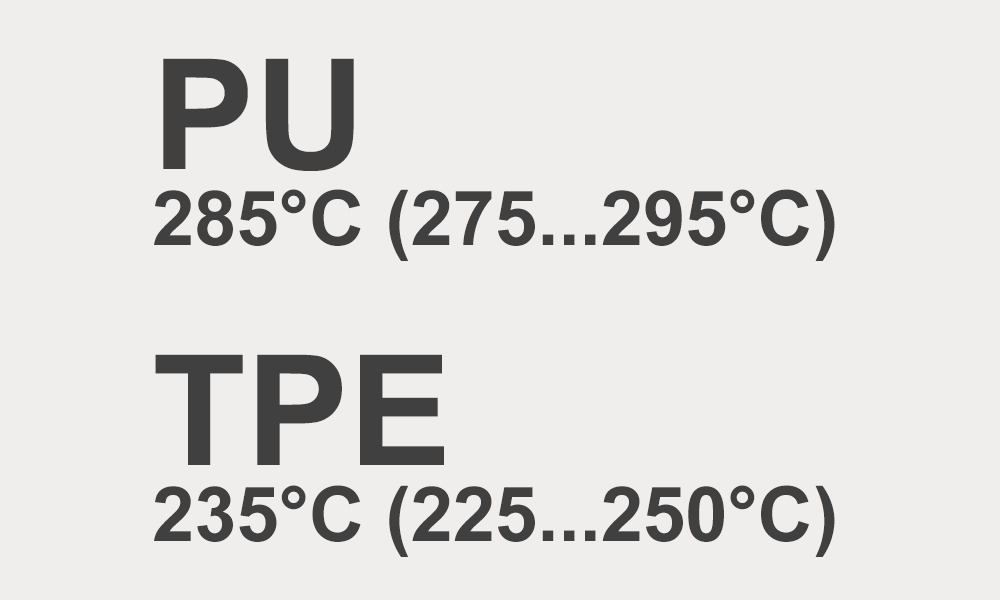

Frequently asked questions about welding technology for PU and TPE

Below we answer important technical topics on the welding of belt profiles and belts. If you miss a topic or have questions about an area, the technical team is very happy to hear from you (+49 7686 907 170 or info@behabelt.com).