Features at a glance

- Very easy to use.

- Reduces operator errors through a fully automatic and controlled welding and vulcanization process.

- Thanks to its exchangeable moulds the HP01 is suitable for splicing many different profiles and fl at belts made of PU and TPE as well as timing belts.

- User friendly operation through self-explanatory menu of controller (no expertise required).

- Perfect welding within minutes.

- Temperature variation is never a concern (no guesswork).

- Real time data logging & diagnostics function for quality assurance of the splice.

- Different types of welds possible (overlap welds, butt welds and angle welds).

- Due to its small size and the hook for hanging up the press during the welding process, the HP01 can be used in confined spaces “on-site”.

- Best welding solution for reinforced profiles (aramid, polyester and steel) through overlap welding.

TECHNICAL DATA

- Heating plate dimensions:

- 120 x 60 mm

- Dimensions (HxWxD):

- 240 x 167 x 200 mm

- Weight:

- approx. 4.800 g

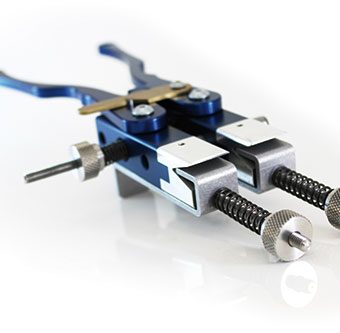

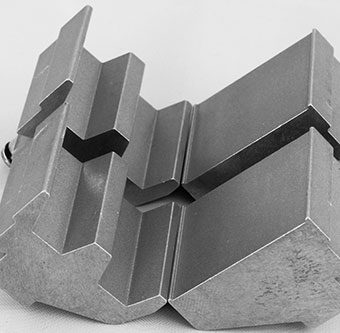

Standard moulds for HP01 Hotpress

Insert profile in the middle of the mould.

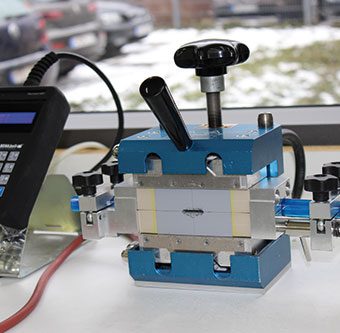

Insert the mould centrally in HP01. Close spindle to form fit.

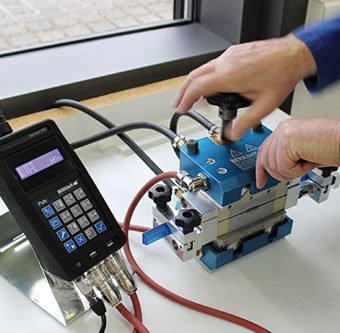

Start automatic welding process using the PPuls-Controller.

Close the spindle again approx. 2 minutes before the end of the process.

Wait for cooling process. Remove the mould.

Remove profile from mould. Remove excess material with side cutter.

SCOPE OF SUPPLY

1 pc. Hot press HP01 AIR

1 pc. Controller HP01

1 pc. Scissors SE02

1 pc. Screwer

1 pc. Scissors AS04

1 pc. Aluminum case

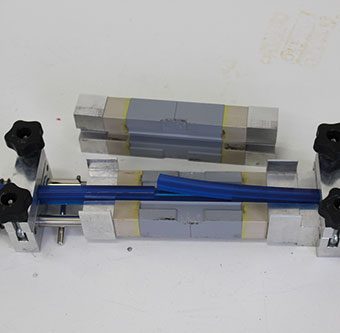

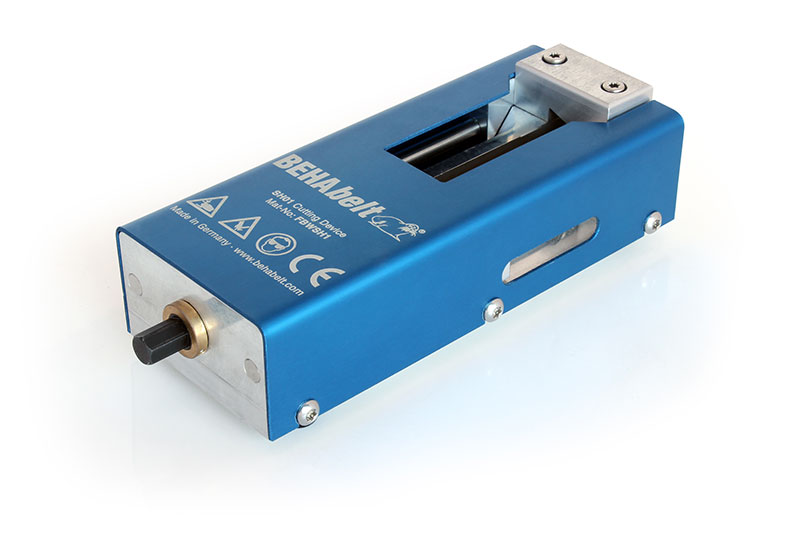

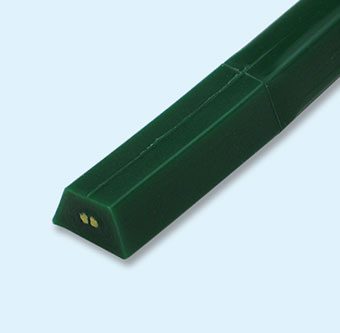

Belt cutter SH01

For precise trimming and preparation of the carrier-reinforced belts for the overlap welding.

For the belt cutting aid, we offer suitable mold nests for the various profiles. A list can be found here.

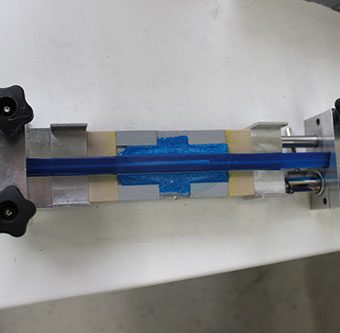

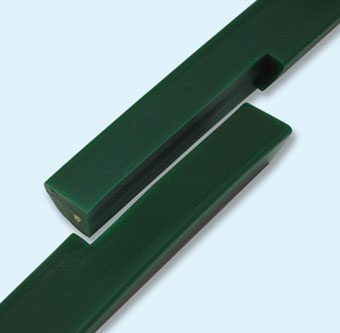

Before the Overlap welding

After the Overlap welding

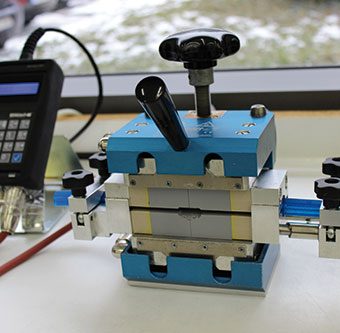

Hot press and CRIMP-Set for belt profiles with steel reinforcement (Canning Industry) BEHAbelt HP01 & RH-2

The new and improved CRIMP connection supports you to achieve perfect results when connecting belts with steel reinforcement.