FEATURES

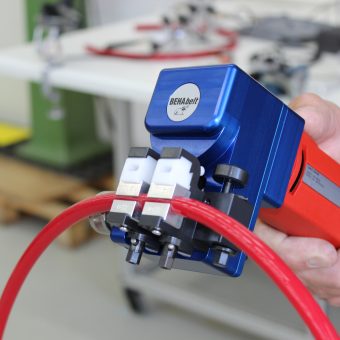

- No long heating-up and set-up times, spliced within seconds.

- Precise pressure and automatical O-positioning prevents uneven welds and premature failure.

- Automatic alignment ensures that the belt ends are aligned perfectly.

- Temperature variation is never a concern (no guess-work).

- Without the risk of injury or fire due to hot metal.

- Due to its small size the RS02 press can be used in confined spaces.

- Thanks to its exchangeable jaws the RS02 is suitable for splicing roundbelts from ∅ 6 mm or V-belts 6 x 4 mm made of polyurethane.

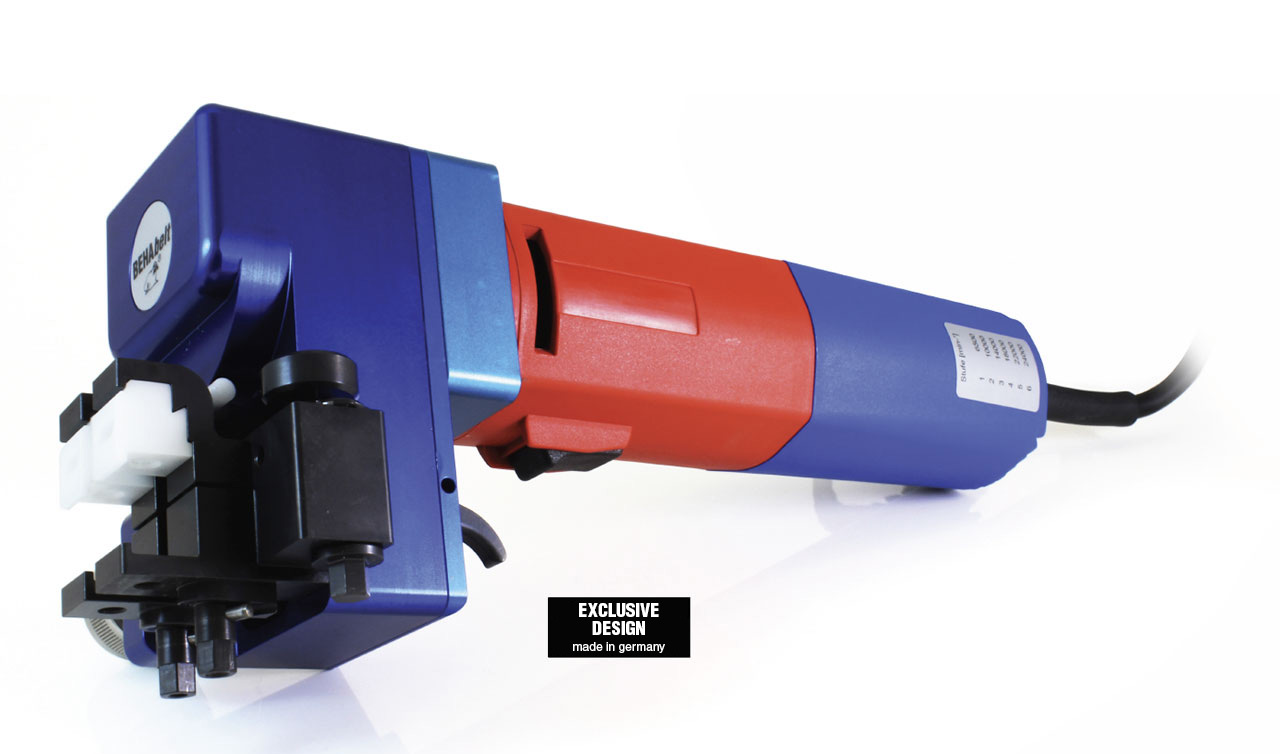

TECHNICAL DATA

- Nominal voltage:

- 230 V AC ±10%

- Frequency:

- 50…60 Hz

- U/min:

- max. 24.000

- Power:

- 500 W

- Dimensions:

- 390 x 105 x 120 mm

- Weight:

- approx. 2,5 kg

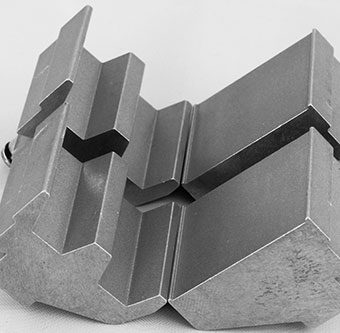

FOR ALMOST ALL PROFILES SUITABLE

v- and round belts

special profiles

twin top v-belts

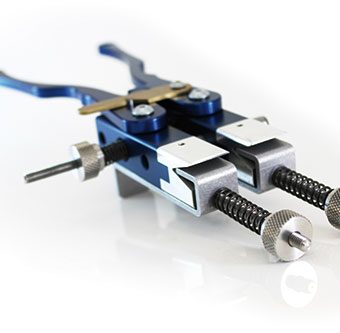

EXCHANGEABLE PROFILE JAWS

BEHAbelt offers you an extensive range of clamping jaws:

Round belts: ∅ 6 to 30 mm

V-belts: 6×4 mm to 22×14 mm

On request, we also manufacture clamping jaws for PU special profiles.

Please download the list of available jaws.

SCOPE OF SUPPLY

1 pc. friction welding machine

1 set standard profiles at your choice

1 pc. torque wrench

1 pc. scissors as02

1 pc. edge cutter se02