Ridge-Top V-belts for the building materials and tile industry

BEHAbelt Ridge-Top-V-belts are made of PU and can therefore be welded quickly and easily. The small contact area makes them ideal for tile glazing plants or brickworks. They also have a high abrasion resistance when transporting heavy and abrasive building materials.

The product range offers different shore hardnesses for variable conveying distances. Special features in the Ridge-Top V-belt range are the blue profiles with weldable reinforcement made of glass-fibre PU and the co-extruded profiles, which combine 2 hardnesses.

co-extruded, PU75A/PU80A transparent/white

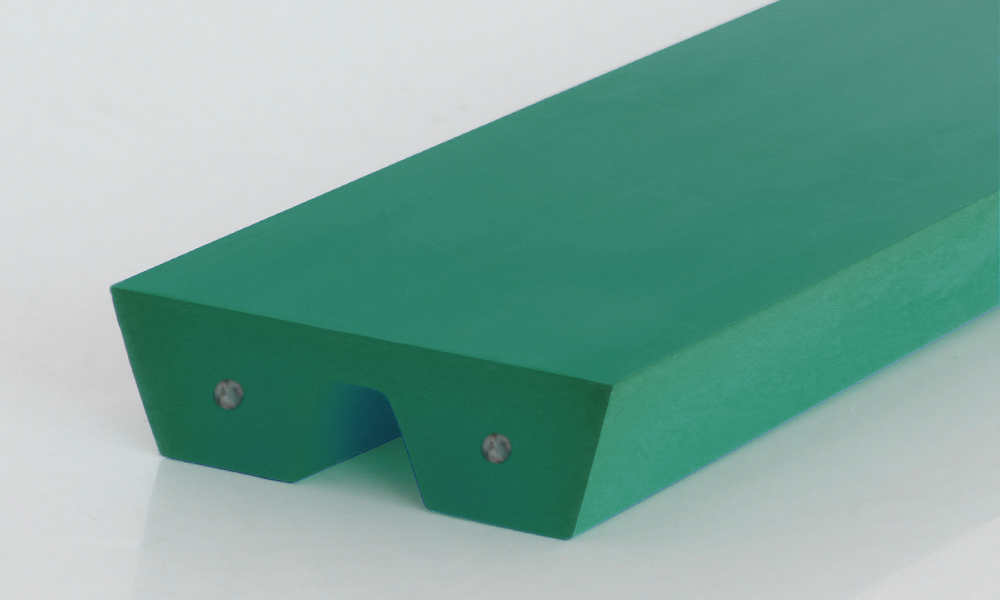

PU85A green, Reinforcement Polyester

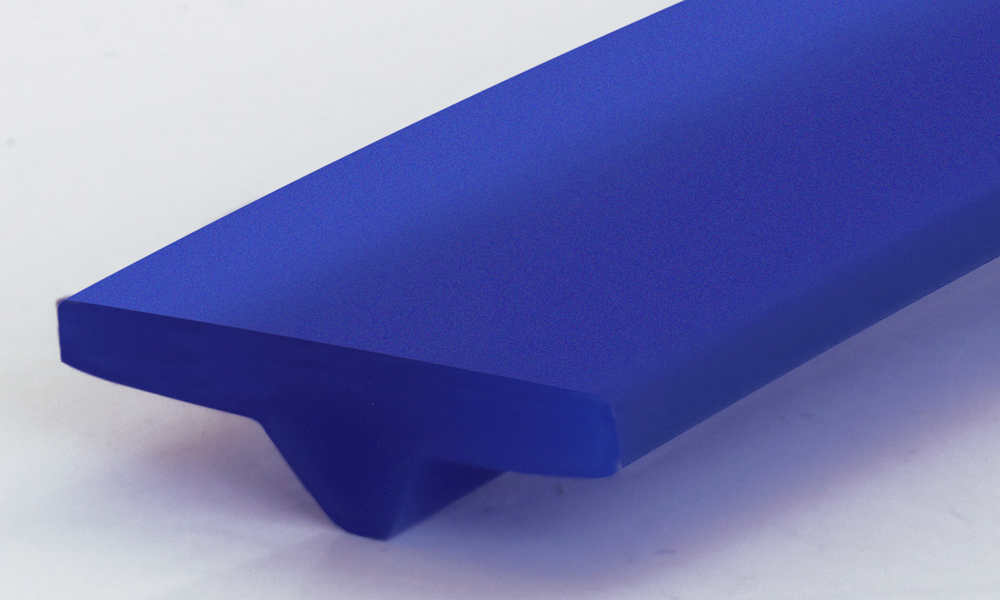

PU85A blue, Reinforcement glass fiber PU

PU85A green

We will be happy to advise you on the selection of the Ridge-Top V-belts.

The sales team and the technical department will be happy to look into your application and help you select the most suitable belt.

In which geometries do you receive the Ridge-Top V-belts?

You can get the Ridge-Top V-belts in 2 shapes, each in the dimensions 17x19mm and 22x25mm.

In addition to the two different hardnesses, the two coextruded profiles also have a groove on the underside of the profile, which allows smaller pulleys.

In which applications are Ridge-Top V-belts used?

Ridge-Top V-belts are mainly used in applications with building materials that require a small contact surface. For example, transport of tiles, bricks or wood.

For the transport of heavy abrasive goods such as bricks, we recommend PU-T profiles with 95°Shore A or raised V-profiles made of polyester.

What is the correct way to weld Ridge-Top V-belts?

Ridge-Top V-belts from BEHAbelt can be purchased by the meter, made up endlessly, delivered or welded on site.

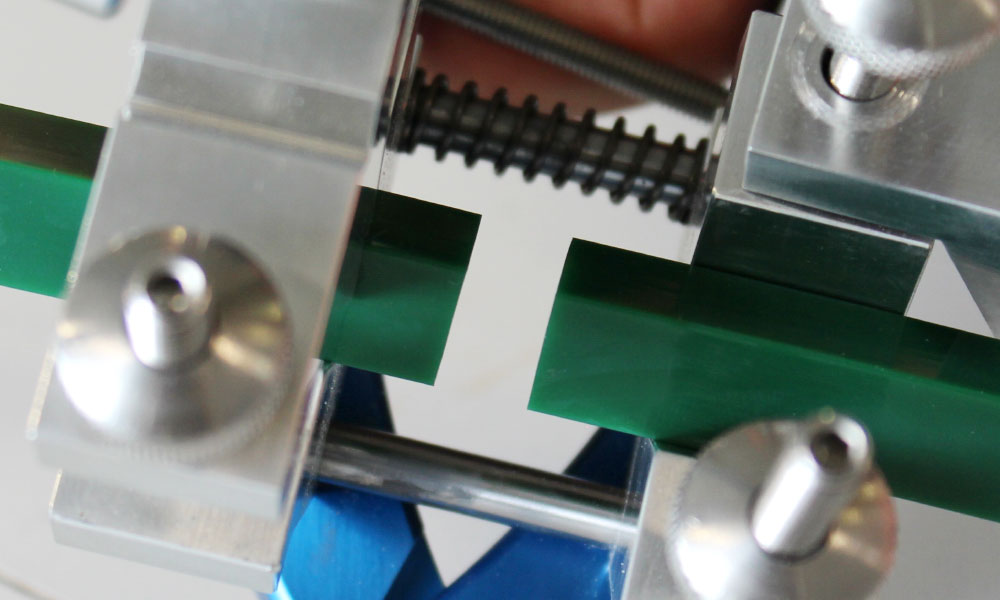

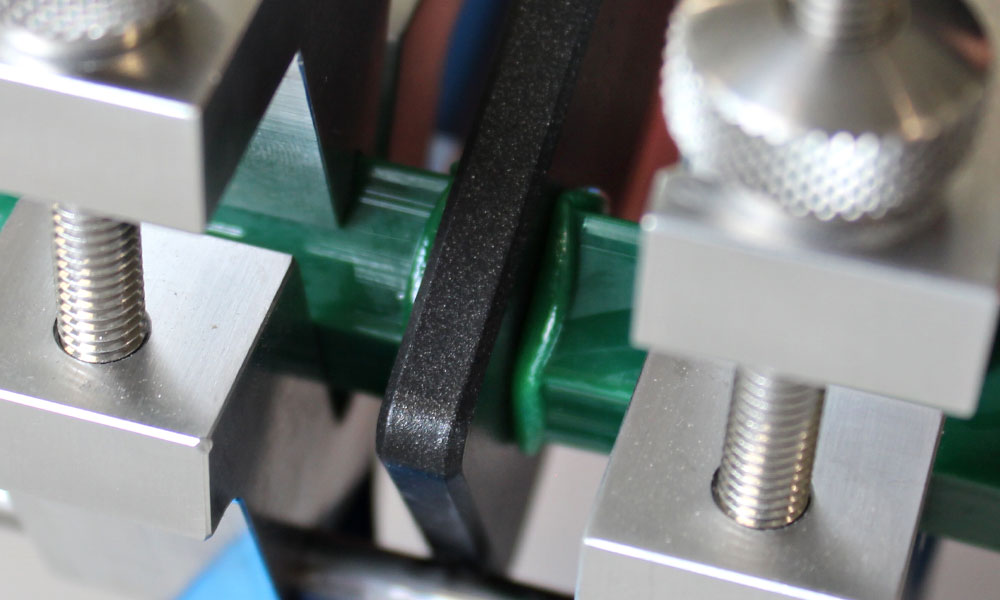

There are two ways of welding Ridge-Top V-belts, either butt welding (for non-reinforced profiles) or overlap welding (for profiles with reinforcement).

Simplified, the welding process mainly takes place in four steps:

Prepare Ridge-Top V-belts

Here the profile ends are cut flat (e.g. with BEHAbelt AS02).

Clamping the belt in the guide unit

The guide clamp (e.g. FZ01 Vario or FZ02/3) ensures perfect alignment of the belt ends to be spliced.

Welding process

For PU belts 290°C are required (for TPE belts 240°C). The BEHAbelt welding units (e.g. EErgo) ensure a constant welding temperature even at different ambient temperatures.

Removing the welding bead

After the welding process and the cooling time, only the weld bead has to be removed by means of a side cutter (BEHAbelt SE02) or a sharp knife.

A special feature for welding belts is the friction welding machine RS02. Here the belt ends are heated and welded by means of friction. This is the fastest and safest method of joining belts endlessly.

What distinguishes Ridge-Top V-belts from other belts?

Quite clearly: the shape, which has a pointed inlet at the transport position.

The superordinate group of Ridge-Top V-belts are the V-belts; these are initially available in ISO 4184 (DIN 2215) dimensions and are supplemented by special designs, such as parallel V-belts, double V-belts or V-belts with a curved surface.

In addition, BEHAbelt offers a very varied portfolio of round profiles: Round belts, hollow round belts and twisted round belts.

In addition, BEHAbelt develops customer-specific profiles thanks to its own toolmaking.

Where can I buy BEHAbelt Ridge-Top V-belts?

Ridge-Top V-belts are available at technical specialised trade or directly at BEHAbelt.

It is important to us to support you with our experience in selecting the suitable ridge-top v-belt for your application.

All Ridge-Tops at one glance Request samplesFurther belt profiles from BEHAbelt

Depending on the material to be conveyed, different belt profiles are required. BEHAbelt is specialized in the production of extruded thermoplastic belt profiles. Thanks to our own tool shop and modern, flexible production facilities, we can also produce customer-specific profiles quickly and cost-effectively.