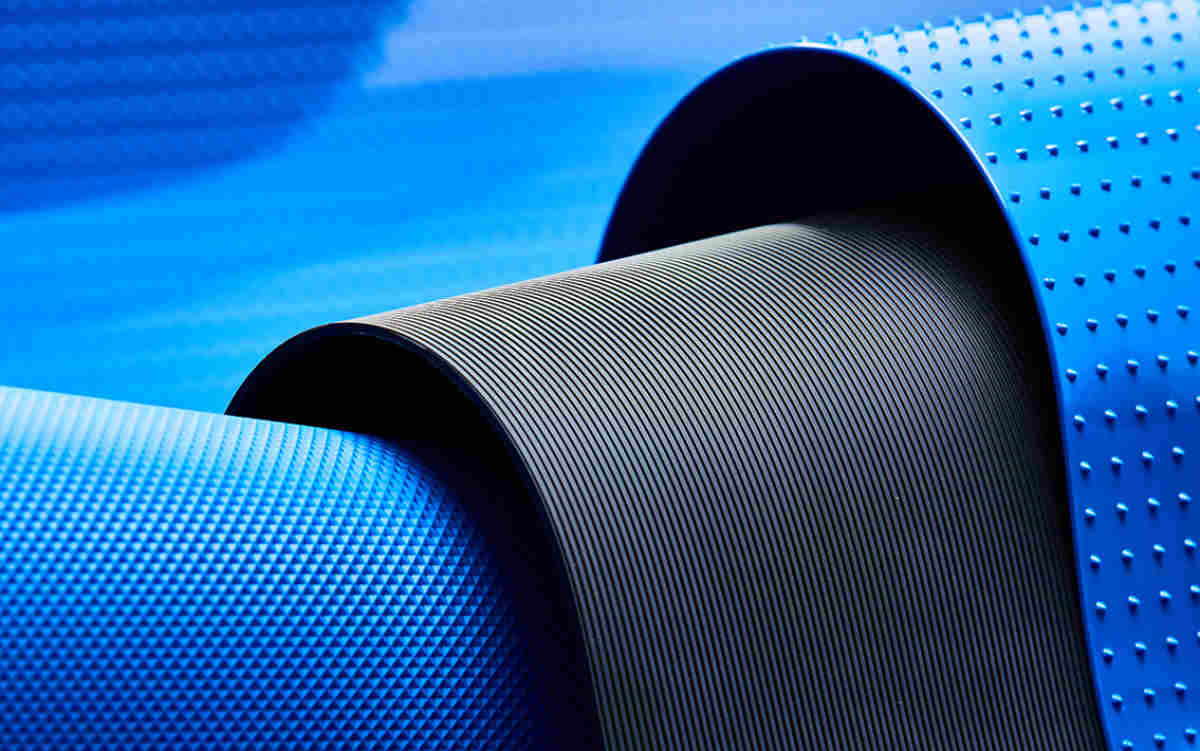

The new conveyor belt with the rough structured surface “RI” allows a good grip of the material to be conveyed while at the same time ensuring gentle transport.

Typical applications for the “RI” conveyor belt

- Feeding systems (cutting machines for vegetables and salads, ham, sausage, cheese, bacon, etc.)

- Transport systems and folding machines in laundries

- Inclined conveyor (to avoid slippage)

- Coating similar to a Supergrip surface for timing and V-belts

Characteristics for the “RI” conveyor belt

- rough structured surface for very good grip with simultaneous gentle transport

- Suitable for direct food contact thanks to FDA-EC conformity

- Easy installation due to elasticity

- Monolithic design enables endless connection by butt welding and welding in the plant

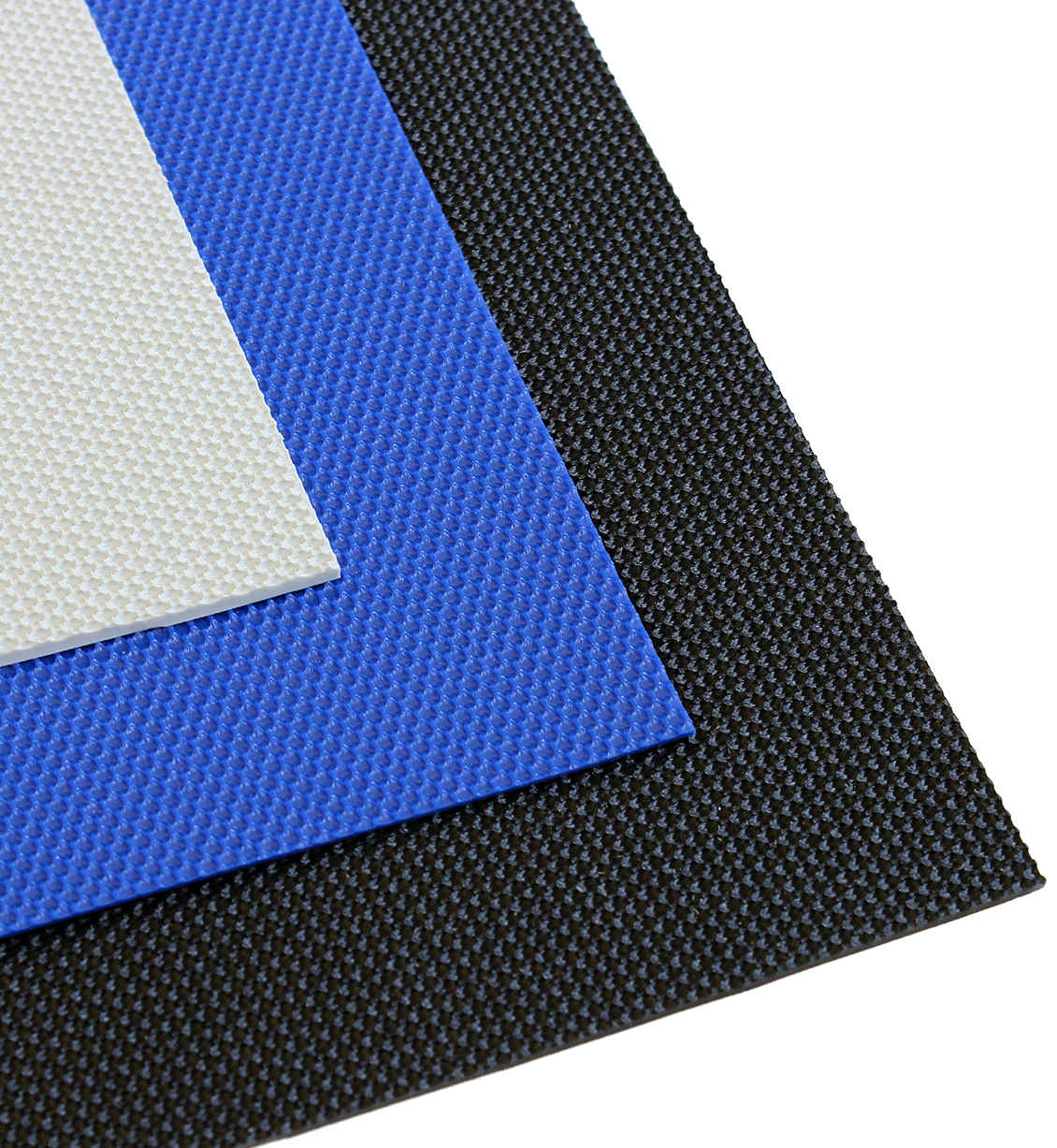

- The conveyor belts are offered in ultramarine blue (2 and 3mm) or black (2mm) as standard. Other colours and thicknesses are available on request.

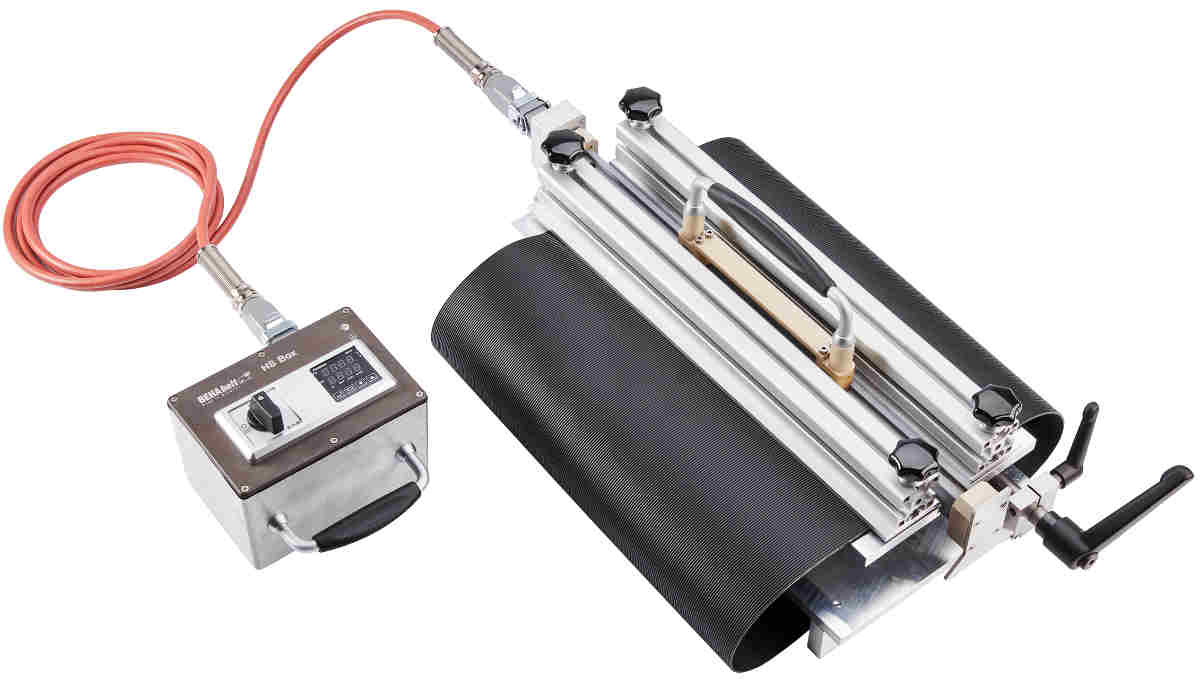

Welding technology for conveyor belts

butt welding up to a width of 800mm

The welding sets HS400 and HS800 were specially developed for butt welding of elastic monolithic conveyor belts.

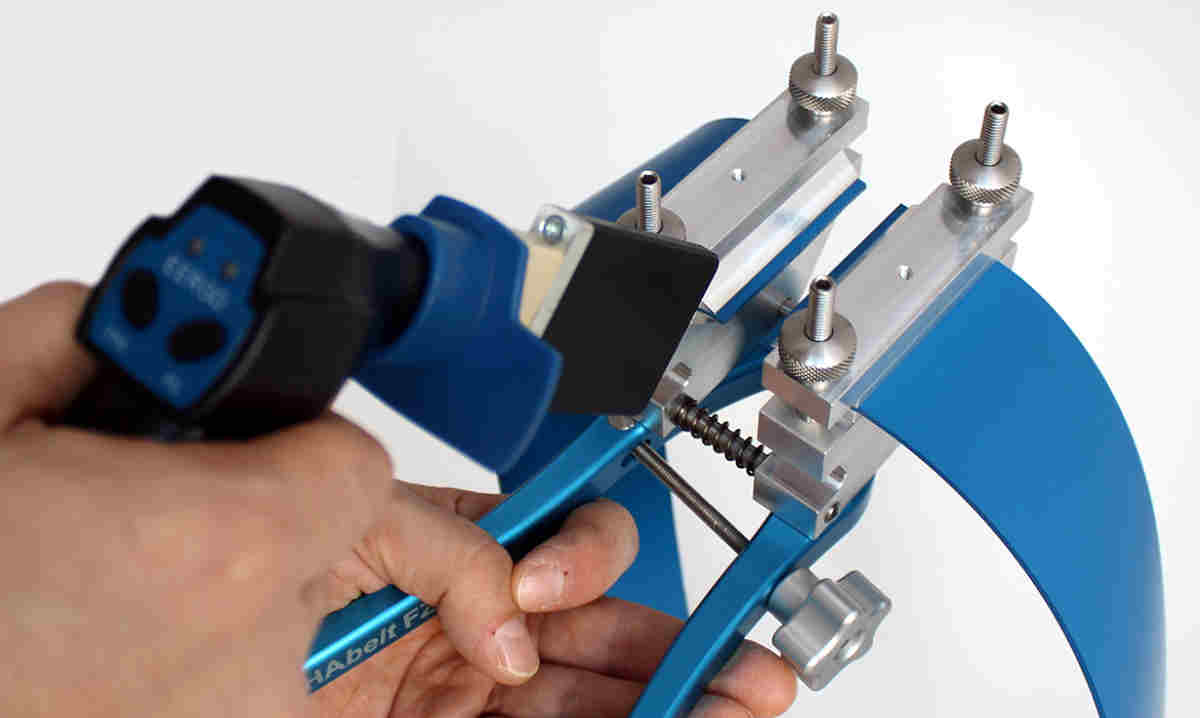

butt welding up to 80 mm width

The combination of the guide clamp FZ02/3F and the welding paddle EErgo 90 allows the easy connection of flat stripes up to 80 mm width.

Elastic monolithic conveyor belts

The variety of combinations of surfaces, material characteristics and colours of the monolithic conveyor belts from BEHAbelt is almost unique on the market. Therefore the contact characteristics of the belt can be optimally adjusted to the application.